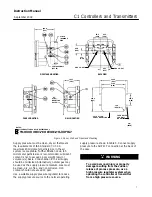

C1 Controllers and Transmitters

Instruction Manual

September 2009

2

Contents (Continued)

Parts Kits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Parts

. . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Parts for Panel, Wall, Pipestand

or Actuator Mounting

. . . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual provides installation,

operating, maintenance, and parts information for

the Fisher C1 Series pressure controllers and

transmitters shown in figure 1. Refer to separate

instruction manuals for information regarding the

control valve, actuator, and accessories.

Do not install, operate, or maintain C1 Series

pressure controllers and transmitters without first

being fully trained and qualified in valve, actuator,

and accessory installation, operation, and

maintenance. To avoid personal injury and property

damage, it is important to carefully read, understand,

and follow all the contents of this manual, including

all safety cautions and warnings. If you have any

questions about these instructions, contact your

Emerson Process Management sales office before

proceeding.

Description

The C1 Series pneumatic pressure controllers and

transmitters use a bellows or Bourdon tube sensing

element to sense the gauge pressure, vacuum,

compound pressure, or differential pressure of a

liquid or gas. The controller or transmitter output is a

pneumatic pressure signal that can be used to

operate a final control element, indicating device, or

recording device.

Unless otherwise noted, all NACE references are to

NACE MR0175

−

2002.

Specifications

Specifications for the C1 Series controllers and

transmitters are listed in table 1. Table 2 explains

available configurations and options.

Educational Services

For information on available courses for C1 Series

controllers and transmitters, as well as a variety of

other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158

−

2823

Phone: 800

−

338

−

8158 or

Phone: 641

−

754

−

3771

FAX: 641

−

754

−

3431

e

−

mail: [email protected]

Installation

WARNING

To avoid personal injury or property

damage resulting from the sudden

release of pressure:

D

Always wear protective clothing,

gloves, and eyewear when performing

any installation operations.

D

Personal injury or property

damage may result from fire or

explosion if natural gas is used as the

supply medium and appropriate

preventive measures are not taken.

Preventive measures may include, but

are not limited to, one or more of the

following; remote venting of the unit,

re

−

evaluating the hazardous area

classification, ensuring adequate

ventilation, and the removal of any

ignition sources. For information on

remote venting of this controller/

transmitter, refer to page 8.

D

If installing into an existing

D

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

Standard Installation

The instruments are normally mounted vertical with

the case/cover as shown in figure 1. If installing the

instrument in any other position, be sure that the

vent opening shown in figure 2 is facing downward.