C1 Controllers and Transmitters

Instruction Manual

September 2009

7

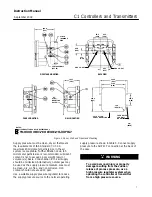

2 INCH

(NOMINAL)

PIPE

VENT ASSEMBLY

(KEY 28)

FOUR HOLES

FOR WALL

MOUNTING

CUTOUT FOR

PANEL MOUNTING

MOUNTING

HOLES

PANEL MOUNTING

WALL MOUNTING

BACK VIEW

PIPESTAND MOUNTING

mm

(INCH)

NOTES:

1. ALL CONNECTIONS ARE 1/4 NPT INTERNAL.

HIGH

−

PRESSURE CONNECTION FOR DIFFERENTIAL

−

PRESSURE UNITS.

2

3

LOW

−

PRESSURE CONNECTION FOR DIFFERENTIAL

−

PRESSURE UNITS.

E1052

101.6

(4.00)

14.3

(0.56) R

244.3

(9.62)

215.9

(8.50)

218.9

(8.62)

142.7

(5.62)

69.1

(2.72)

23.1

(0.91)

65.8

(2.59)

63.5

(2.50)

63.5

(2.50)

180.8

(7.12)

8.7

(11/32)

KNOCK

−

OUT

KNOCK

−

OUT

Figure 2. Panel, Wall, and Pipestand Mounting

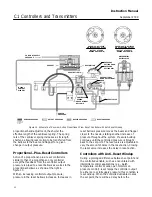

Supply pressure must be clean, dry air that meets

the requirements of ISA Standard 7.0.01. A

maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant

content is not to exceed 1 ppm weight (w/w) or

volume (v/v) basis. Condensation in the air supply

should be minimized. Alternatively, natural gas may

be used as the supply pressure medium. Gas must

be clean, dry, oil

−

free, and noncorrosive. H

2

S

content should not exceed 20 ppm.

Use a suitable supply pressure regulator to reduce

the supply pressure source to the normal operating

supply pressure shown in table 5. Connect supply

pressure to the SUPPLY connection at the back of

the case.

WARNING

To avoid personal injury or property

damage resulting from the sudden

release of process pressure, use a

high pressure regulator system when

operating the controller or transmitter

from a high pressure source.