C1 Controllers and Transmitters

Instruction Manual

September 2009

32

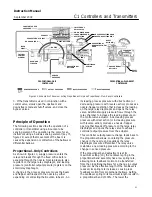

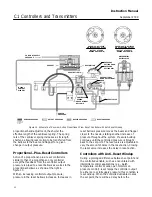

Key

Description

Part Number

Note

Key 2 is used as both a supply gauge and an

output gauge on units without a process

pressure gauge. A quantity of 2 is required

for these units. On units with a process

pressure gauge (key 106), key 2 is used for

the output gauge. A quantity of 1 is required

for these units.

Use key 3 for supply pressure indication

when a process pressure gauge is installed.

Key 3 installs on the supply pressure

regulator.

2*

Supply and Output Pressure Gauge, w/o process

pressure gauge (1/8

−

inch connecting stem), (2 req’d)

Dual scale

Brass/Plastic

0

−

2.0 kg/cm

2

and 0

−

30 psig

11B8577X042

0

−

4.0 kg/cm

2

and 0

−

60 psig

11B8577X052

SST

0

−

2.0 kg/cm

2

and 0

−

30 psig

11B8583X032

0

−

4.0 kg/cm

2

and 0

−

60 psig

11B8583X052

Triple scale

Brass/Plastic

0

−

2.0 bar, 0

−

0.2 MPa, and 0

−

30 psig

11B8577X012

0

−

4.0 bar, 0

−

0.4 MPa, and 0

−

60 psig

11B8577X022

SST

0

−

2.0 kg/cm

2

and 0

−

30 psig

11B8583X012

0

−

4.0 kg/cm

2

and 0

−

60 psig

11B8583X022

2*

Output Pressure Gauge, w/process pressure

gauge (1/8

−

inch connecting stem), Brass/Plastic

Triple scale

0

−

2.0 bar, 0

−

0.2 MPa, and 0

−

30 psig

11B8577X012

0

−

4.0 bar, 0

−

0.4 MPa, and 0

−

60 psig

11B8577X022

3*

Supply Pressure Gauge, w/process pressure

gauge (1/4

−

inch connecting stem), Brass/Plastic

Triple scale

0

−

2.0 bar, 0

−

0.2 MPa, and 0

−

30 psig

11B8579X022

0

−

4.0 bar, 0

−

0.4 MPa, and 0

−

60 psig

11B8579X032

Note

Controllers with bellows sensing element

use only the 2.0 bar, 0 to 0.2 MPa, and 0 to 0

to 30 psig triple scale brass and stainless

steel process pressure gauges. Differential

pressure controllers do not use a process

pressure gauge.

4*

Process Pressure Indicator Gauge (use only when specified)

Triple scale

Stainless steel

0

−

2.0 bar, 0

−

0.2 MPa, and 0

−

30 psig

11B8584X022

0

−

20 bar, 0

−

2.0 MPa, and 0

−

300 psig

11B8584X012

0

−

69 bar, 0

−

6.9 MPa, and 0

−

1000 psig

11B8584X032

High Temp, silicone

1N873804142

5*

Bourdon Tube

See following table

6

Dial, aluminum

7

Screw, nylon (transmitters only)

Key

Description

Part Number

8*

Cantilever Spring, S30200

3

−

15 psi range

GE31702X012

6

−

30 psi range

GE31701X012

9

Nameplate, aluminum

10

Control Pressure Block

For gauge pressure instruments

w/o process pressure gauge

CF8M FMS 20B58 for standard, NACE and oxygen service

w/process gauge

SST

11

Plug, S31600 (not shown)

used with gauge pressure only

1 req’d for standard/NACE

2 req’d for oxygen service

12

Machine Screw, steel pl (4 req’d)

13

Lockwasher, steel pl/zn pl (4 req’d)

14

Pressure Connection, S31600

Use w/process gauge

15

Pipe Plug, steel pl (not shown)

Use w/process gauge, not used w/Bourdon tube protector

16*

Connecting Link

, Bourdon tube instruments only

Std., 18

−

8 SST

1L379641012

16

Connecting Link, Bourdon tube w/optional travel stop,

18

−

8 SST

17

Lockwasher, steel pl (2 req’d)

Use w/optional Bourdon tube travel stop

18

Machine Screw, steel pl (2 req’d)

Use w/optional Bourdon tube travel stop

19*

Relay Gasket

Std Temp, chloroprene

1C897403012

Hi Temp, silicone

1N873804142

20*

O

−

Ring

, nitrile

1C376206992

21*

Gasket

, chloroprene, (not shown)

1C328603012

22

Mounting Screw for reset restriction valve

1/4

−

20 UNC, steel pl (not shown)

23*

Control Tubing Assembly, 304 SST

For Bourdon tube instruments

w/o process pressure gauge

NACE

1H3011000A2

Oxygen Service

1H3011X0012

w/process pressure gauge

1J2530000A2

23

Control Tubing Assembly, SST/vinyl

used with NACE compliant Bourdon tube

24*

Relay Tubing Assembly, 304 SST

GE33948X012

25*

Compensator Tubing, 304 SST

GE28421X012

26*

Reset Tubing, 304 SST

GE30128X012

*Recommended spare parts

1. This part is included in the Controller Repair Kit.