C1 Controllers and Transmitters

Instruction Manual

September 2009

18

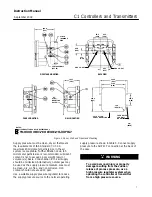

PRESSURE SETTING

DIAL (KEY 6)

ADJUSTER SCREWS (KEY 48)

CALIBRATION ADJUSTER (KEY 36)

FLAPPER (KEY 40)

NOZZLE (KEY 54)

SPAN ADJUSTMENT KNOB

ZERO ADJUSTMENT KNOB

(KEY 58)

GE34729

−

B

E1061

Figure 11. Transmitter Adjustment Locations

pressure of 80 psig with rising process pressure and

from full supply pressure to zero at 20 psig with

falling pressure. (This is for a direct

−

acting

controller.) The differential gap is:

5.5 bar

*

1.3 bar

6.9 bar

100%

+

60%

80 psig

*

20 psig

100 psig

100%

+

60%

(

)

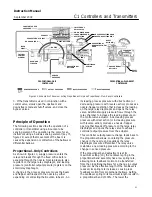

From figure 10, the proportional band dial setting

should be approximately 4.5; rotate the proportional

band adjustment knob to 4.5.

6. Setting the process pressure

For a Direct

−

Acting Controller:

a. Rotate the pressure setting knob to the

pressure at which the controller output is to

switch to the upper switching point (zero to full

supply pressure) with rising process pressure. In

the above example, this pressure is 5.5 bar (80

psig).

b. Increase pressure to the sensing element

while monitoring the output pressure gauge. The

controller output pressure should switch from

zero to full supply pressure when the upper

switching point is reached with rising input

pressure.

Note

If the upper switching point is not

correct, adjust the nozzle to correct

the error. Repeat step 6b until the

input pressure and upper switching

point are at the desired setting.

c. With falling input pressure, the output should

switch from full supply pressure back to zero

when the lower switching point is reached.

Reverse

−

acting controllers produce the opposite

response.

7. Vary the process pressure and observe the

switching points. Widen or narrow the differential

gap by rotating the proportional band adjustment

knob, then repeat the above steps.

If the output is within the limits stated, refer to the

startup procedures in this section. If the output

pressure cannot be adjusted within the limits stated,

refer to the maintenance procedures.