54

HPS-III-Heißkanalsystem_Inbetriebnahme-Sicherheitshinweise-Voraussetzungen_BA_V-2-0_EN

Start-up and instructions for operation

6. Start-up and instructions for operation

6.1 Safety instructions

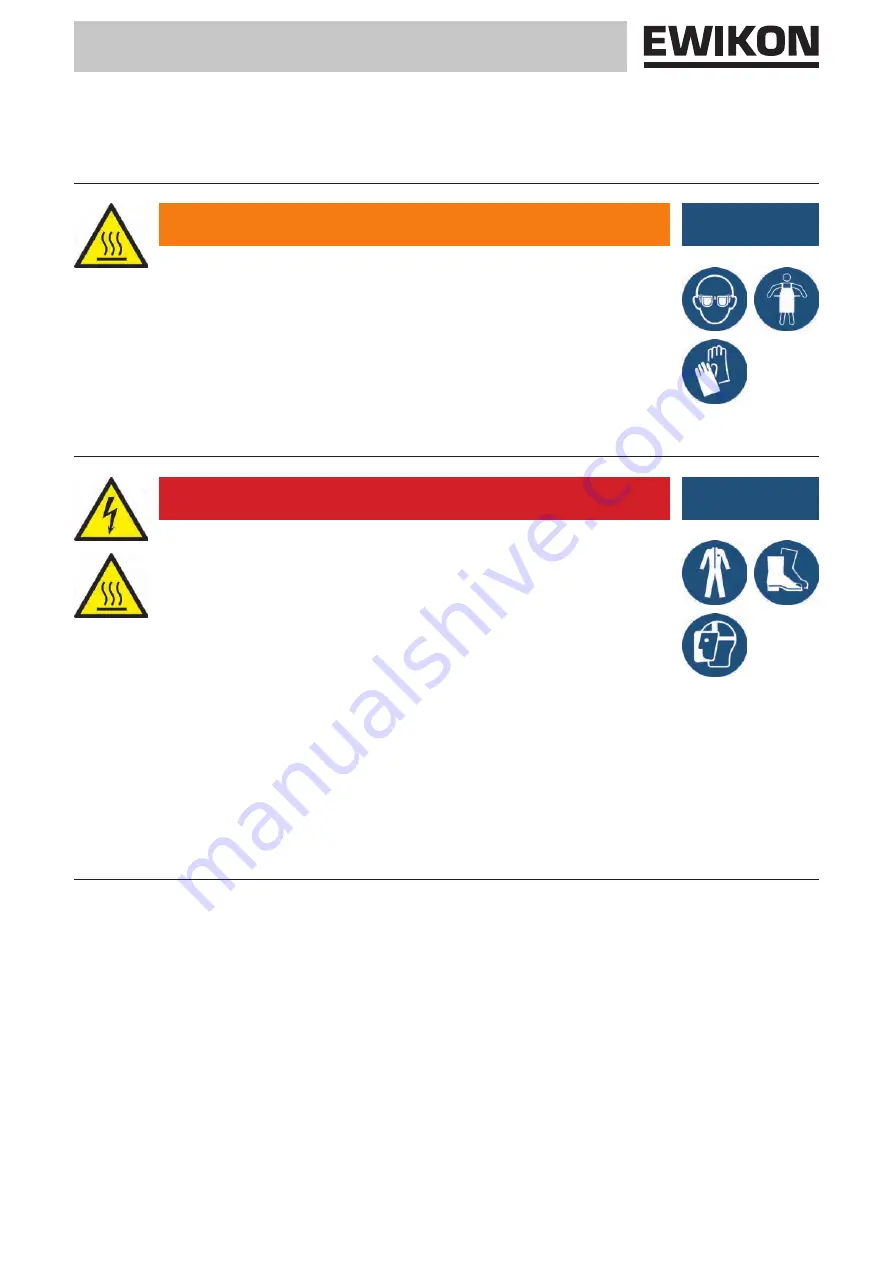

WARNING!

PPE

Unwanted sudden escape of melt caused by thermal degradation or gas release

of plastic material

Unwanted escape of melt caused by different thermal expansion of materials

due to temperature differences

Heavy burns to body and extremities.

•

Before operation the system must be heated through for at least 3-5 min.

•

Only process materials which are approved for use with the system.

•

The safety devices of the injection moulding machine must be active and working

HAZARD!

PPE

Insufficient protective conductor connection to the injection moulding machine

Risk of deadly electric shock or severe injuries due to live components.

The operator must ensure that during startup of hot runner single tips or hot runner

systems all electrical system components have been wired to to the protective con-

ductor system of the injection moulding machine or are protected by equivalent safety

measures before applying electric voltage. When applying electric voltage to systems

or to system components beyond specified normal operation, sufficient ground earth

connection or equivalent safety measures must be ensured for each component.

Raised injection pressure

The system is designed for an injection pressure of 2000 bar. When the cavity pres-

sure is too high (e.g. by overpacking a cavity without limiting the injection pressure)

components of the hot runner system may break and hot plastic melt can escape.

Injection moulding processes must only be carried out with maximum pressures of

2000 bar. If the process requires higher pressures a written permission of EWIKON

Heißkanalsysteme GmbH is needed.