25

HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Installation

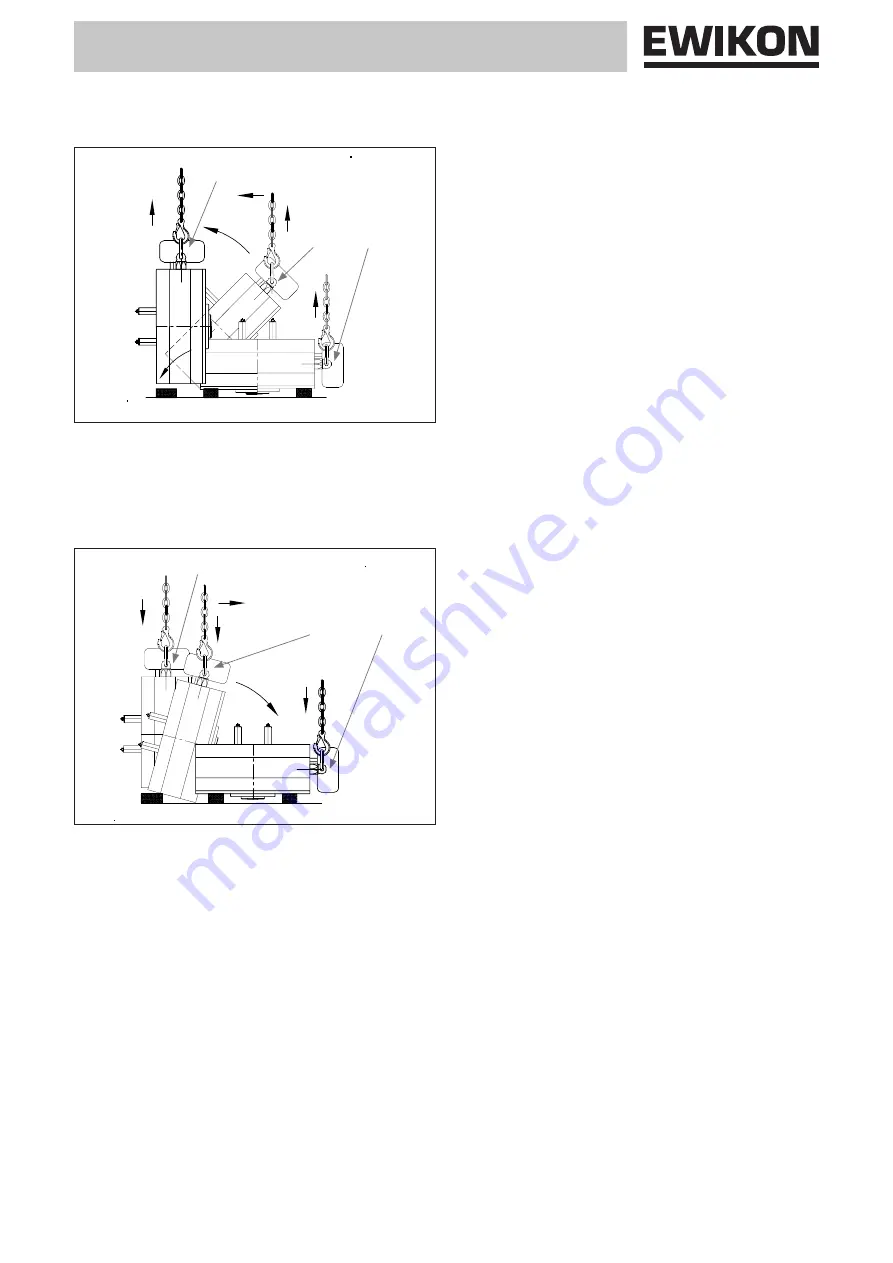

Putting hot runner assemblies (hot halves, mould plates, manifolds or L2X systems)

from lying (horizontal) into upright (vertical) position.

1. The hot runner assembly must be placed on an even,

non-slip surface.

2.

Screw in attachment swivels and affix them to a crane.

3. Put a wooden lath on the working surface and secure

against slipping. It has to be positioned in such a way that

when the external lateral surface of the hot runner assem-

bly is erected it can be supported by the wooden lath.

4. Slowly lift the hot runner assembly until the lateral surface

touches the wooden lath. Continue lifting the assembly

until it reaches upright position following the movement of

the hot runner assembly with the crane so that the crane

hook is always perpendicular to the attachment point .

5. When the hot runner assembly hangs freely in upright po-

sition, remove the wooden lath and carefully place the hot

runner assembly on a surface or move it using a crane.

Picture 20: Putting hot runner assemblies (hot halves or mould

plates or manifolds) from lying (horizontal) into upright (vertical)

position

z362-10

100% load capacity

50% load capacity

Putting hot runner assemblies (hot halves, mould plates, manifolds or L2X systems)

from upright (vertical) into lying (horizontal) position.

1. Put a wooden lath on the working surface and secure

against slipping. it has to be positioned in such a way

that the external lateral surface of the hot runner assem-

bly can rest on the wooden lath when it is dropped.

2. Use the crane to position the freely hanging hot runner

assembly over the wooden lath

3. Slowly drop the hot runner assembly until the external

lateral surface touches the wooden lath. Continue drop-

ping the hot runner assembly carefully until it tilts and

touches the working surface. Follow the tilting movement

of the hot runner assembly with the crane so that the cra-

ne hook is always perpendicular to the attachment point.

4. Carefully put the hot runner assembly on the working

surface following the movement of the hot runner as-

sembly with the crane so that the crane hook is always

perpendicular to the attachment point. Make sure there is

a solid substructure so that protruding components are

not damaged.

Picture 21: Putting hot runner assemblies (hot halves, mould plates

or manifolds) from upright (vertical) into lying (horizontal) position.

z362-11

100% load capacity

50% load capacity