17

HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Technical data

3.4.2 Cooling agent

The use of unsuitable cooling agents may result in deposits and corrosion in the component to be cooled. This will negatively

affect the functionality of the hot runner system. Components of the hot runner system may be damaged by a reduced coo

-

ling performance in the worst case. Cooling agents (water) have to satisfy the following minimum requirements:

•

Cooling by tap water is not recommended since hard water can cause deposits and corrosion.

•

The water has to be clear, colourless and odourless.

•

It has to be free from any floating or suspended matters.

•

A warranty on the resistance of components to be cooled against corrosion attacks cannot be given.

However, the use of suitable cooling agents can considerably enhance this resistance.

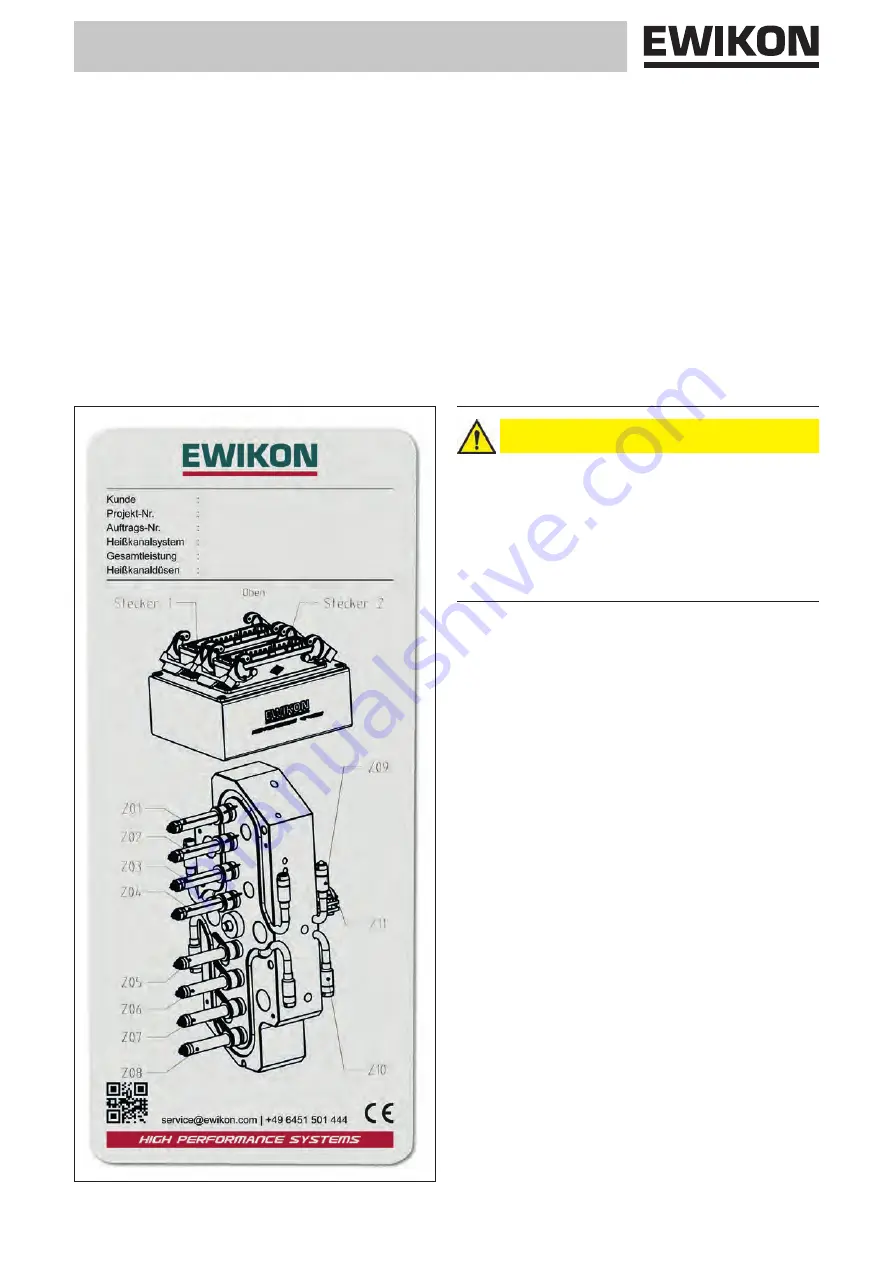

3.5 Type plate

Picture 1: Type plate

The system type plate is to be displayed prominently on the

operator side of the mould. Hot halves are delivered with the

type plate already mounted.

The type plate indicates project number, order number, type

of hot runner system, overall performance, drive unit type,

nozzles used and, if necessary, other important specifica

-

tions.

For the exact allocation of heater zones and contact pins

in the plugs please refer to the wiring scheme in the order

specific documents.

Respect operating temperatures

Each hot runner system is individually designed for the material to be

processed. Therefore, the specified operating temperatures must be

observed. The temperature difference ∆T between hot runner tempe

-

rature THK (processing temperature) and mould temperature TWZ,

must be strictly adhered to.

•

Non-observance may cause an escape of melt inside the mould

(∆T too low) or damage to components (∆T too large).

CAUTION!