Chapter 3 Installation and Wiring

590SP Digital Product Manual

3 - 6

3

▼

Drive must

Control Contactor

Coil

DC Contactor

Wiring

G

H

AC Contactor

Wiring

I

Dynamic Brake

Contactor

Interlock

Contactor to Zero

Speed

Jumper C5 to

+24 VDC

(terminal C9)

Switch C5 to +24

VDC (C9) thru

n/o contactor

auxiliary

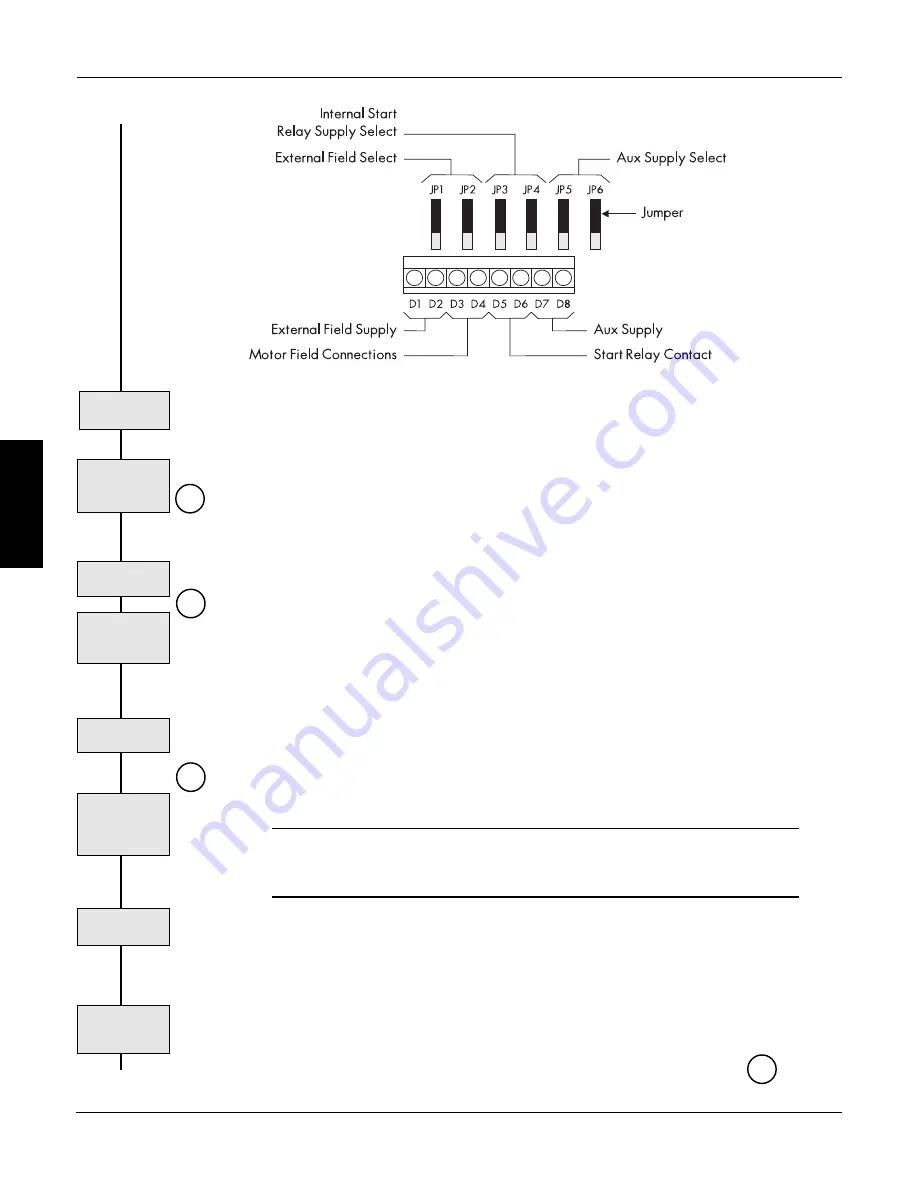

Figure 3.6- Auxiliary Control Jumpers

Check Jumpers

JP5 and JP6

(line). Move jumpers JP5 and JP6 from positions 2 and 3 to positions 1 and 2 to power the control

transformer externally. The supply is protected by a 1.6 amp fuse.

Motor Isolation

Isolate the motor from power by either breaking the controller input supply with an AC contactor or

the output power with a DC contactor. The 590SP Digital drive must control this contactor to ensure

that current flow is never interrupted while the thyristors are firing.

AC Contactor Wiring

AC contactor wiring is shown in the upper right portion of the wiring diagram in Figure 3.3. Use a

two-pole, normally-opened contactor rated to handle the AC voltage and supply current. Wire the

contactor poles between branch AC circuit protection and the supply input terminals (L1 and L2).

Permanently enable the drive by jumpering terminal C5 (ENABLE) to terminal C9 (+24 VDC).

Always isolate input power to the drive by dropping out the AC contactor power before servicing

the equipment.

NOTE. The control supply must be supplied externally when using an AC contactor.

Connect it as described above in Control Power Wiring.

DC Contactor Wiring

Wire a suitably rated DC contactor between the drive output terminals (A+ and A-) and the motor

armature. Connect terminal C5 (ENABLE) to terminal C9 (+24 VDC) through a normally opened

auxiliary of the main contactor. This keeps the drive disabled until the main contactor closes, and

disables the drive when the contactor opens.

WARNING!

When isolating the armature using a DC contactor, the field remains powered while

the contactor is de-energized.

Dynamic Braking

The DC contactor wiring schematic in Figure 3.3 shows wiring for an optional dynamic braking

application. Dynamic braking requires a DC contactor with an additional normally closed pole rated

to carry full load current upon closing.

NOTE. Dynamic brake contactor poles are rated to make, but not interrupt DC motor

current. To avoid damaging the normally closed contact, interlock the drive's zero

speed output signal to the drive start logic to prevent the drive from restarting until the

motor has reached standstill. This zero speed interlock relay logic is shown at in

Figure 3.3.

J

1

2

3

▼

Summary of Contents for 590SP

Page 2: ......

Page 16: ...1 4 590SP Digital Product Manual 1 Chapter 1 Introduction ...

Page 18: ...2 2 2 590SP Digital Product Manual Chapter 2 Identification ...

Page 31: ...Figure 3 3 Wiring Circuit Diagram for 590SP Digital Drive ...

Page 41: ...4 10 4 590SP Digital Product Manual Chapter 4 Start up and Adjustment DIGTIAL ...

Page 67: ...6 590SP Digital Product Manual Chapter 6 Service and Maintenance 6 6 ...

Page 89: ...B Appendix B Using the Man Machine Interface App B 4 590SP Digitial Product Manual ...

Page 125: ...Appendix C Setup Parameters 590 DRV Digital DC Drive Product Manual App C 36 C ...

Page 149: ...Appendix D I O Configuration System Menu App D 24 D 590SP Digital DC Drive Product Manual ...

Page 150: ...t t t t Figure D 20 590SP Digital Software Block Diagram ...

Page 160: ...590SP Digital Product Manual App E 10 E Appendix E MMI Parameter List ...

Page 168: ...Appendix G RS232 System Port P3 590SP Digital Product Manual App G 6 G ...

Page 194: ...Appendix H RS422 Communications Ports P1 P2 590SP Digital Product Manual App H 26 H ...

Page 220: ...App L 6 590SP Digital Product Manual L Appendix L 590SP DRV Option ...

Page 221: ...Figure L 5 Wiring Circuit Diagram for 590SP Digital DRV Drive ...

Page 259: ...590SP Digital Product Manual App M 38 Appendix M Special Blocks and Application Notes M ...