SC-F2000

Revision C

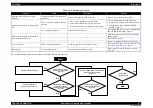

TROUBLE SHOOTING

Remedies for Print Quality Troubles

46

Confidential

Bandings in the feeding direction.

The amount of TF feeding was changed

using the Operation Panel.

---

Adjust the amount of TF Feeding properly.

The PRINT HEAD is not adjusted

properly.

---

Carry out the following adjustments.

ANGULAR ADJUST AND CHECK

HORIZONTAL

ADJUST AND CHECK HEAD VERTICAL

Feeding on the Platen is abnormal.

---

Carry out the following adjustment.

TF ADJUSTMENT

TF SCALE or TF ENCODER BOARD

ASSY is abnormal.

1. Is the TF SCALE damaged or contaminated?

2. Is the TF SCALE installed correctly?

3. Is the TF ENCODER BOARD ASSY installed

correctly?

1. Clean the TF SCALE.

2. Reinstall the TF SCALE and TF ENCODER

BOARD ASSY.

3. Replace the TF SCALE

and/or TF

ENCODER BOARD ASSY

The tension of the TF TIMING BELT

is not proper.

---

Carry out the following adjustments.

ADJUST TF BELT TENSION

ADJUST TF MOTOR BELT TENSION

TF MOTOR ASSY failure

---

Replace the TF MOTOR ASSY.

Bandings in the carriage movement

direction.

If the location where the error occurs

varies in the print area

---

See

“ Troubleshooting when color unevenness and

such occurs in the print area” (Page 47)

.

The PRINT HEAD is not adjusted

properly.

Have the following adjustments been made properly?

ANGULAR ADJUST AND CHECK HORIZONTAL

(Head Inclination Adjustment)

ADJUST AND CHECK HEAD VERTICAL (Head

Slant Adjustment)

Carry out the adjustments if it is not adjusted

properly.

ANGULAR ADJUST AND CHECK

HORIZONTAL

ADJUST AND CHECK HEAD VERTICAL

PG is not adjusted properly.

Is the PG adjusted properly?

CR SCALE or CR ENCODER

SENSOR failure

1. Is the CR SCALE damaged or contaminated?

2. Is the CR SCALE installed properly?

3. Is the CR ENCODER SENSOR installed correctly?

1. Clean the CR SCALE.

2. Reinstall the CR SCALE and CR ENCODER

SENSOR.

3. Replace the CR SCALE and CR ENCODER

SENSOR

.

The tension of the CR TIMING BELT

is not proper.

---

Correct the tension of the CR TIMING BELT.

Table 2-2. Print Quality Troubles

Symptom

Cause

Check Item

Remedy

Summary of Contents for SC-F2000 Series

Page 1: ...SC F2000 Direct To Garment Printer SERVICE MANUAL SECP13002 Confidential ...

Page 10: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 29: ...Confidential C H A P T E R 2 TROUBLESHOOTING ...

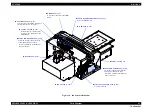

Page 52: ...Confidential C H A P T E R 3 DISASSEMBLY ASSEMBLY ...

Page 192: ...Confidential C H A P T E R 4 ADJUSTMENT ...

Page 285: ...Confidential C H A P T E R 5 MAINTENANCE ...