SC-F2000

Revision C

ADJUSTMENT

TF Adjustments

255

Confidential

[Blue]:

Button or menu name on the program screen /

[Black]:

Button or menu name on the operation panel of the printer

4.13.3 TF Timing Belt Tension Adjustment

REQUIRED TOOLS

Sonic tensimeter U-507

MASS: 001.3

g/m

WIDTH: 006.0

mm/R

SPAN: 0066

mm

Any tools to flip the timing belt

EXECUTION MODE

Normal Mode

STANDARD VALUE

11.5 ± 1.5 N

PROCEDURE

1.

Remove the following part in advance.

Rear Cover Sub Assy

2.

Turn the printer ON.

3.

Start the Service Program and select

[TF Timing Belt Tension adjustment]

.

4.

Click

[RUN]

.

The TABLE ASSY moves front and back once, then stops in the front position.

5.

Input the following information on the belt into the tensimeter.

MASS:

001.3 g/m

WIDTH:

006.0 mm/R

SPAN:

0066 mm

6.

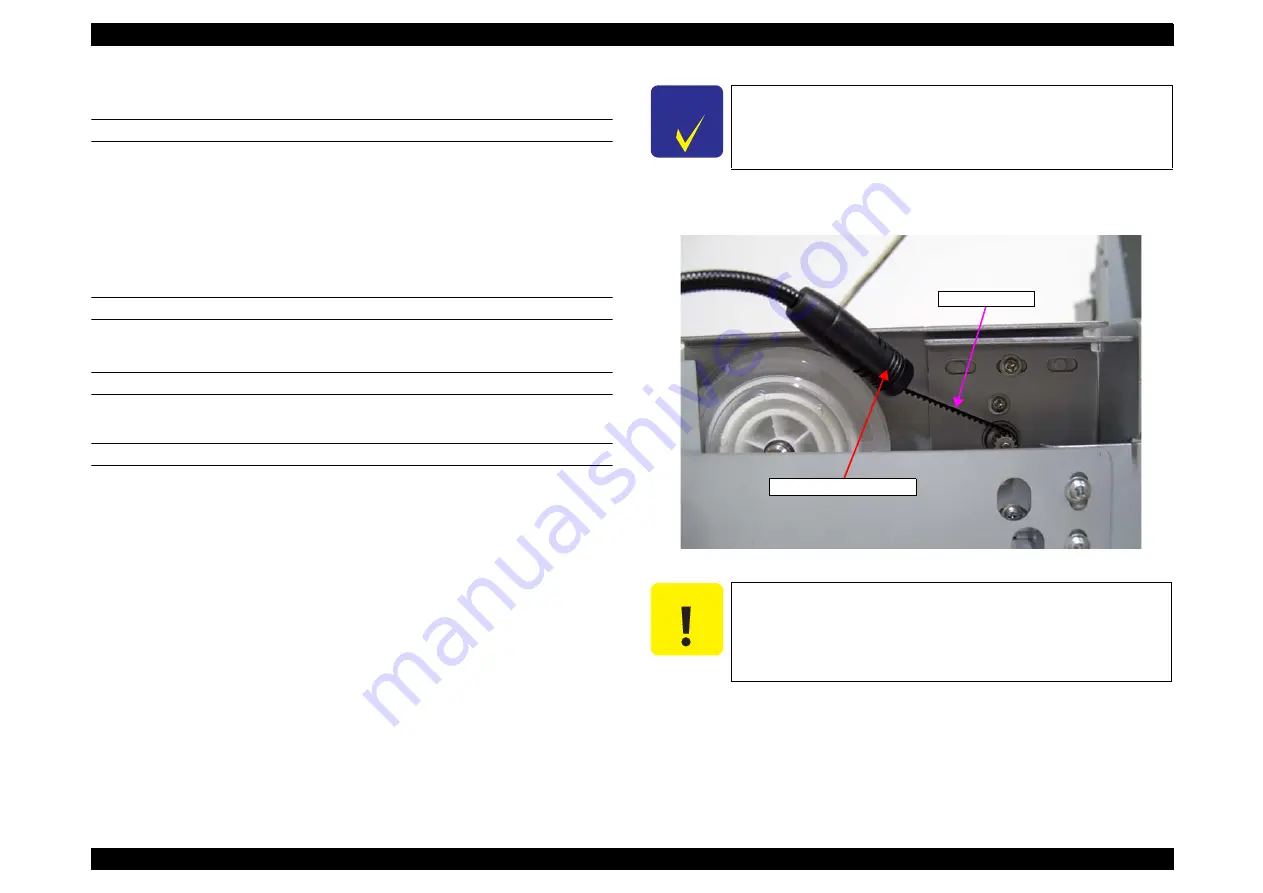

Bring the microphone of the tensimeter close to the belt as shown in

.

7.

Press the

[MEASURE]

button on the tensimeter, and flip the timing belt with

tweezers or a similar tool.

Figure 4-56. TF Timing Belt Tension Adjustment

8.

Measure the belt tension three times and check if the average is within the

standards.

Within the standards: Go back to

and check again, then the adjustment

is completed.

Out of the standards: Go to

C H E C K

P O I N T

The distance between the microphone and the belt surface should

be 5 mm or less, but do not let it touch the belt.

C A U T I O N

Make sure to measure the tension of the upper belt. Otherwise,

the result may not be correct.

Flip the timing belt as weak as the tensimeter can measure it.

Be careful not to let the microphone touch the timing belt when

flipping the belt.

TF Timing Belt

Measuring Microphone

Summary of Contents for SC-F2000 Series

Page 1: ...SC F2000 Direct To Garment Printer SERVICE MANUAL SECP13002 Confidential ...

Page 10: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 29: ...Confidential C H A P T E R 2 TROUBLESHOOTING ...

Page 52: ...Confidential C H A P T E R 3 DISASSEMBLY ASSEMBLY ...

Page 192: ...Confidential C H A P T E R 4 ADJUSTMENT ...

Page 285: ...Confidential C H A P T E R 5 MAINTENANCE ...