SC-F2000

Revision C

TROUBLE SHOOTING

Remedies for Print Quality Troubles

45

Confidential

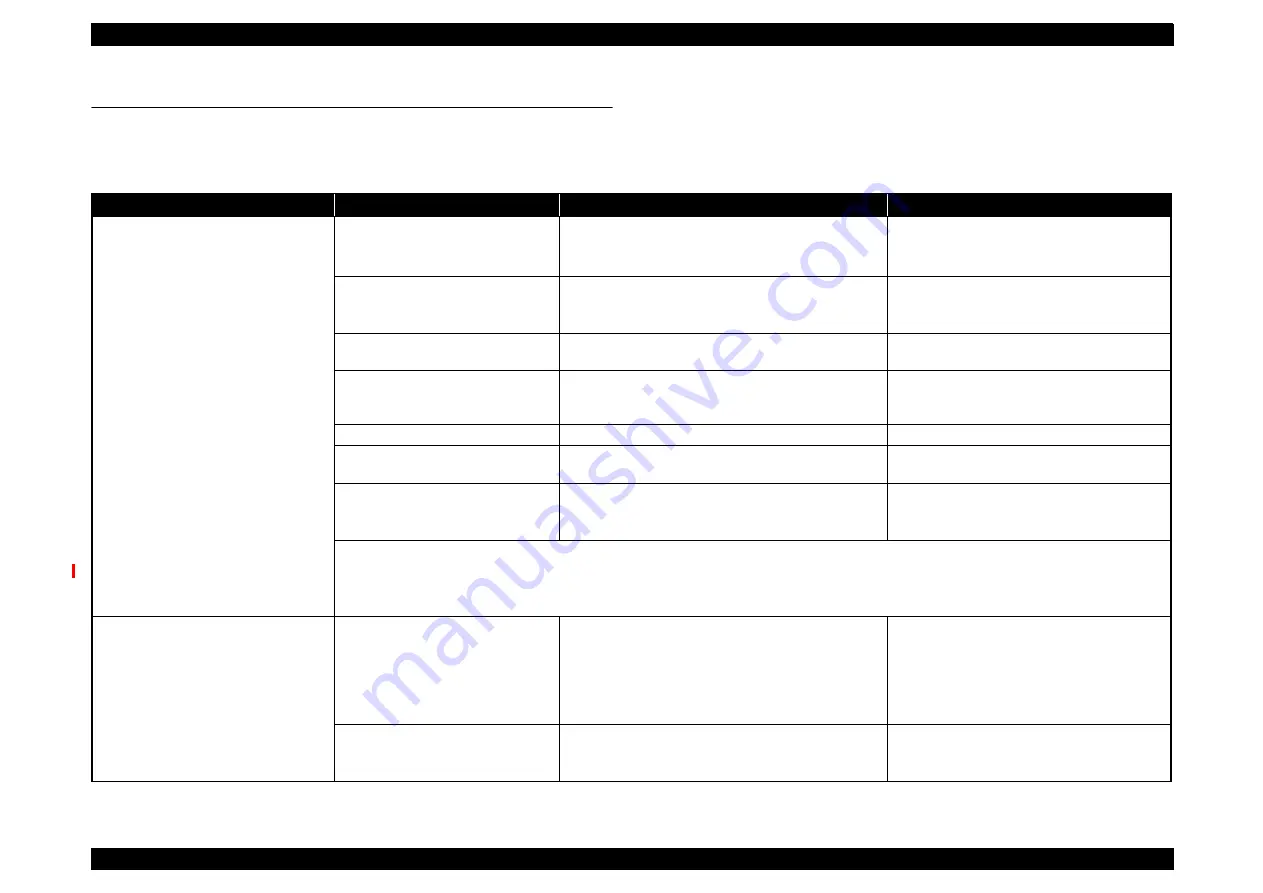

2.4 Remedies for Print Quality Troubles

This section provides troubleshooting of print quality troubles classifying them by observed symptom. Before performing troubleshooting, refer to

and print

nozzle check pattern. Examine the printed pattern, and if any missing segment is found, perform the Print Head cleaning.

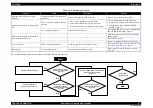

Table 2-2. Print Quality Troubles

Symptom

Cause

Check Item

Remedy

The nozzles are still clogging after

cleaning.

The wiper is contaminated or wiping

the PRINT HEAD is not performed

properly.

1. Is the wiper contaminated?

2. Is the wiper cleaner damaged?

3. Check if the cloth wiper is taken up.

The Suction Cap and Cap (PUMP CAP

ASSY) are contaminated.

Is the Cap contaminated?

1. Clean the Suction Cap.

2. Replace the Cap (PUMP CAP ASSY).

There is a foreign material on the

PRINT HEAD.

Is there any foreign material on the PRINT HEAD?

Remove the foreign material.

There is something wrong in the pump

tube and the cleaning (suctioning of

ink) is not performed properly.

Is the pump tube bent or getting caught between

surrounding parts or components?

Correct the routing of the pump tube, if necessary.

The ink is leaking.

Is there any ink leakage observed in the ink flow paths?

If any leakage is found, correct it.

There are some bubbles inside the ink

path.

Are there any bubbles observed in the ink flow paths?

Run a head cleaning.

The HEAD FFC is not connected

correctly.

Is the HEAD FFC connected properly? Check for

abnormalities such as a ripped terminal cover or slant

connection.

1. Reconnect the HEAD FFC.

2. If the error persists, the HEAD FFC may be

broken. Replace the HEAD FFC.

If any of the remedies above does not help, replace the following parts one by one.

DAMPAR KIT.

PRINT HEAD.

MAIN BOARD (The fuse may have blown)

Horizontal or vertical lines look

misaligned.

The PRINT HEAD is not adjusted

properly.

Have the following adjustments been made properly?

ANGULAR ADJUST AND CHECK HORIZONTAL

(Head Inclination Adjustment)

ADJUST AND CHECK HEAD VERTICAL (Head

Slant Adjustment)

Carry out the adjustments if it is not adjusted

properly.

ANGULAR ADJUST AND CHECK

HORIZONTAL

ADJUST AND CHECK HEAD VERTICAL

PG is not adjusted properly.

1. Is the height of Platen adjusted properly with the Height

Adjustment Lever?

2. Is Bi-D adjusted properly?

Summary of Contents for SC-F2000 Series

Page 1: ...SC F2000 Direct To Garment Printer SERVICE MANUAL SECP13002 Confidential ...

Page 10: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 29: ...Confidential C H A P T E R 2 TROUBLESHOOTING ...

Page 52: ...Confidential C H A P T E R 3 DISASSEMBLY ASSEMBLY ...

Page 192: ...Confidential C H A P T E R 4 ADJUSTMENT ...

Page 285: ...Confidential C H A P T E R 5 MAINTENANCE ...