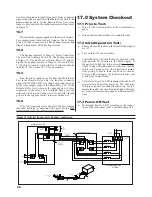

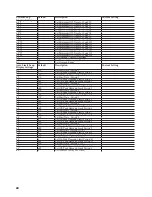

Figure 8: Typical Clothes Dryer Interconnection

14.4

Remove one of the two wires from the dryer’s circuit

breaker and wire-nut (cap) this wire so that it will not short

to anything. Turn on dryer’s circuit breaker and attempt to

start the dryer. If the dryer starts, the detached wire is the

correct wire to attach to the power relay. To verify this, turn

off the dryer and the dryer’s circuit breaker and reattach

this wire to the circuit breaker. Remove the opposite phase

wire from the circuit breaker the wire-nut (cap) this wire.

Turn circuit breaker on and start the dryer again. This time

the dryer’s motor should NOT start. If it does (dryer starts

with either wire disconnected), your dryer may require

some internal wiring modifi cations before it can be con-

nected to the 9312. To do this, contact dryer manufacturer

or consult dryer wiring diagram.

14.5

Turn off the circuit breaker and remove the correct

wire. With the correct wire removed, the dryer motor should

start. Run two short lengths of #10 AWG wire between

the circuit breaker panel and the Relay Unit. Wire-nut the

disconnected wire to one of the short lengths of wire in the

circuit breaker panel. Wire-nut the other end of this wire

to one red lead of the relay’s contact. Wire-nut the relay’s

other red lead to the other short length of wire that returns

into the breaker panel. Connect the other end of the wire

back to the dryer’s circuit breaker as shown in Figure 9.

Figure 9: Dryer Interconnection Schematic

24

15.0 Wiring Low-Voltage

Relays to Heat Pumps &

Air Conditioners

15.1

Turn off all circuit breakers for heat pumps, air condi-

tioners, air handlers, or electric furnaces.

15.2

Connecting air conditioners and/or heat pump com-

pressors to the Energy Sentry unit is normally accom-

plished by inserting a 3 Amp low voltage signal relay in

series with the low voltage 24 VAC thermostat control

loop as shown in Figure 10. (Generalized Drawing). This

can be done in one of two ways: 1) Use the low voltage

relays on the Data/Link PC Board for Circuits #2 and #3 or

2) Use remote low voltage relays.

Normally the relay is inserted in the common (usually

red) wire. In heat pumps, this allows the compressor to be

shed in both heating and cooling modes and also causes the

blower and any auxiliary heat to be shed at the same time.

In the event that breaking the red wire is incompatible with

an electronic thermostat, the relay will be inserted in the

compressor relay (yellow). It is strongly recommended that

auxiliary electric strip heat in air handlers be controlled

separately using remote power or signal relays.

Figure 10: Typical Low Voltage Load Interconnection

16.0 Connecting the

9312 to an Electric

Furnace

When connecting an air handler with heat strips

or furnace to the 9312, the most effective method is to

install a Remote Relay Unit at the air handler or furnace.

(Available from Brayden Automation Corporation - P/N

FG9291A). This Relay Unit contains 2 to 6 relays for con-

nection to each individual heat strip in the furnace. These

relays are connected to the Main Relay Unit by means of

paired cable, normally one pair per relay. For example,

for 4 remote relays, an #18 AWG eight conductor cable is

required. Twisted pairs are recommended for this applica-

120V

30A Relay

Dryer

Circuit

Breaker

Disconnect here

and insert relay

120V N

Dryer

M

Heating

Element

120V

Pilot

Relay

Compressor

Relay

Circuit

Breaker

120V N

Air Conditioner/Heat Pump

Disconnect thermostat loop

here and insert relay

24VAC

Thermostat

Relay Unit

Relay

Breaker

Breaker

Panel/

Load

Center

To Dryer

Break here and insert

relay in series

Neutral