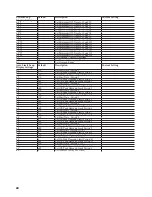

3.0 Pre-Installation

System Check List

3.1 Parts Check

Check package contents to ensure it contains the fol-

lowing parts:

Quantity

Part Number

Description

1

FG9341A

9312 Control/Display Unit

2

8420-3028

200 Amp

Current Transformer

or

8420-3029

400 Amp

Current Transformer

1

Relay Unit: 1 of 2 types

FG9302A-

XXXIXXX

Surface Mount Indoor

NEMA1

or

FG9302A-

XXXRXXX

Rain Tight Outdoor NEMA

3R

* For an expanded system (32 control points) 2 Relay

Units are required

4

9000-02101

Control/Display Unit

Mounting Clips

4

2520-1001

Control/Display Unit

Mounting Screws

1

09000-67102

Control/Display Unit

Mounting Template

1

09312-

94100A

Owner’s/Installation

Manual

Note:

Digits marked with “X” may vary depending with

the number and type of relays, system size, type of enclo-

sure, alarm, and current transformer options.

Note:

Notify your Energy Sentry dealer if any parts are

missing.

3.2 System Overview

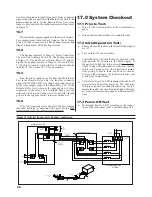

The Energy Sentry 9312 Demand Management System

consists of three general pieces. They are: the Control/

Display (C/D) Unit, the Relay Unit, and the Current Trans-

formers. Figure 3 shows the General System Confi guration.

The C/D Unit mounts inside the home, usually in a general

living area such as the kitchen, hallway, or family room.

The Relay Unit mounts next to the circuit breaker panel.

The Current Transformers mount in the circuit breaker

panel around the main incoming feeder cables.

Installation Manual

17

1.0 Introduction

This manual contains instructions for the installation,

checkout, and programming of the Energy Sentry 9312

Demand Management System. In order to ensure proper

installation and warranty coverage, please read this manual

thoroughly before proceeding with the installation.

Note:

All wiring must be installed in accordance with

national and local electrical codes.

Important:

If the 9312 is to be connected to a heat

pump compressor or air conditioning compressor, please

refer to Appendix B for Minimum On/Off-Times.

2.0 Tools & Materials

Required

2.1 Tools Required

• Flat blade type screwdriver

• Phillips head screwdriver

• Drywall Knife

• Standard crimping tool (needed if optional

crimp-on spade terminals are used)

• Amp-Clamp Current Sensor (if available)

• Digital Volt Meter (required for trouble

shooting only)

2.2 Materials Required

(not provided)

• Four 1/4” x 1” lag bolts and/or appropriate hard-

ware for mounting Relay Unit.

• 15 Amp single pole circuit breaker for the 9312’s

120 VAC Power Supply.

• Suffi cient length of 4 Conductor Control Cable

-Energy Sentry P/N - 0715-0009, or Belden #9156 or

equivalent. This cable has 4-#18 AWG Conductors, 300V

rated. Do not use thermostat wire as it may cause the 9312

to read power incorrectly. Use of thermostat wire may

void warranty.

• Suffi cient length of appropriate hookup wire

(#14 AWG) to connect 120 volt power and ground from

the circuit breaker panel to Relay Unit.

• Suffi cient conduit, #10 AWG or #12 AWG

wire (depending on load size), and associated hardware

to connect the circuit breaker panel to Relay Unit (if

required).