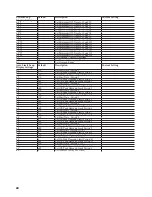

Figure 4: Locating and Mounting the Display Panel

19

Rain Tight Relay Unit

(P/N 9302A-XXXRXXX) “RT”

This Relay Unit is provided with a 15” x 12” x 4”*

NEMA 3R Rain-tight enclosure. Four holes for mounting

are provided: two located directly below the chassis which

hold the electronics and two located at the bottom center

of the enclosure. This unit is surface mounted with four

1/4” x 2” lag bolts or other appropriate hardware.

Expansion Relay Unit

(P/N 9302X-XXXXXXX)

This unit is used in an expanded system. Loads 9

through 16 are controlled with this unit.

*Relay Unit size may vary depending on number of

relays and other factors.

5.2 General Mounting Procedure

5.2.1

Mount enclosure(s) in an upright vertical position

near the circuit breaker panel, with the top of the enclosure

being no higher than 6’ above the ground. Use four 1/4” x

1” lag bolts and appropriate mounting hardware to secure

the unit. The studs for the relay plate must be on the upper

part of the box. (Mounting bolts not provided.)

Caution:

Outdoor enclosures (NEMA 3R) should be

mounted where they will receive the least possible amount

of direct sunlight. Flush mount and surface mount enclo-

sures (NEMA 1) must be mounted indoors only.

5.2.2

Connect the Relay Unit(s) to the circuit breaker

panel with metal conduit to be run from the appropriate

knockout(s), if required. A 1-1/4” conduit must be installed

to accommodate up to sixteen load wires size #10-#12

AWG and three #14 AWG wires for 120V power to unit.

An additional conduit must be run for all Class 2 voltages,

including four #18 AWG Current Transformer wires,

remote relays, and wiring to the low voltage relays on the

Data/Link PC Board. This conduit must use a knockout

that enters in the Class 2 voltage compartment. This com-

partment is found on the right side of the relay box.

A separate conduit may also be required for the control

cable (0.375” diameter).

5.2.3

If installing an Expansion Relay Unit, follow the pro-

cedure in paragraph 5.2.2.

5.2.4

Vacuum out all dry wall dust, metal chips, wood chips,

and other foreign objects which may affect operation of

the system.

6.0 Running Control

Cable

After the location of the Control/Display Unit and the

Relay Unit(s) have been determined and mounted, run the

control cable from the Relay Unit to the C/D Unit, leaving

suffi cient cable length for a 12” service loop at both the

C/D Unit and the Relay Unit.

To avoid any possible interference, do not run control

cable next to or parallel to any high voltage (Class 1)

Wires.

Caution:

Control cable must

not

run through the main

circuit breaker panel.

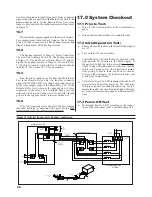

7.0 Wiring Control

Cable to C/D Unit

7.1

Remove cover from C/D Unit by pulling the cover

outward fi rst on one side and then on the other side. Be

extremely careful not to damage the hinge posts which

protrude out approximately 1/2” on each side of the bottom

front of the unit.

7.2

Pass the control cable through the square hole in the

rear of the enclosure, and through the 3/8” diameter hole

in the Data/Link PC Board. Strip cable jacket back about

3 to 4 inches. Strip insulation approximately 1/2” off of

each wire end.

7.3

The control cable consists of 4 #18 AWG conductors.

These are typically Black, White, Green and Red. Connect

the wires as shown in Table 4 (on page 21) and in Figure 5

on the next page.

7.4

Ensure the Red/Green conductors are connected to the

top two screw terminals. Red to terminal CD1. Green to

terminal CDC3. The White/Black conductors are connected

to the bottom two terminals. White to terminal CD2. Black

to terminal CDC4. Refer to Figure 5 or wiring diagram on

Relay Unit cover.

5.4"

8"

8"

C

L

7.15"

59"

FROM

FLOOR

CONTROL/

DISPLAY

UNIT

CUTOUT