Operation 33

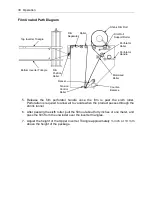

When complete, the scrap film should follow the route to the scrap take-up spool as

shown.

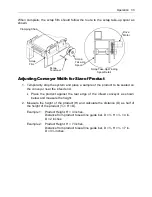

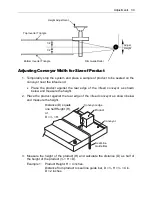

Adjusting Conveyor Width for Size of Product

1. Temporarily stop the system and place a sample of the product to be sealed on

the conveyor near the infeed end.

Place the product against the rear edge of the infeed conveyor as shown

below and measure the height.

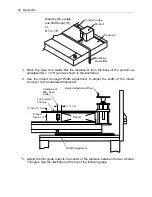

2. Measure the height of the product (H) and calculate the distance (D) as half of

the height of the product (½ × H = D).

Example 1: Product Height, H = 4 inches.

Distance from product to seal line guide bar, D = ½ H = ½ × 4 in.

D = 2 inches.

Example 2: Product Height, H = 7 inches.

Distance from product to seal line guide bar, D = ½ H = ½ × 7 in.

D = 3½ inches.

Clamping Chain

Scrap

Film

Scrap

Tensioner

Scrap

Take-Up

Spool

Scrap Take-Up Winding

Spool Detail

Drive

Motor

Summary of Contents for Value VSA2530TK-V1

Page 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Page 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Page 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Page 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Page 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Page 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Page 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Page 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Page 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Page 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Page 88: ......