Introduction 7

Safety

Read this manual carefully and make it available to everyone connected with the

supervision, maintenance, or operation of this machine. Additional copies are available

on request (Eastey.com/contact-us).

The development of a good safety program that is rigidly enforced is absolutely

imperative when involved in the operation of industrial equipment. Our machinery is well

designed and includes extremely important safety features. Proper installation, safe

operation, and regular maintenance and upkeep are of far greater importance than our

design. Only properly-trained individuals following rigidly enforced safety rules, as

recommended by ANSI and OSHA should be allowed to operate these machines.

Be very careful when operating, adjusting, or servicing this equipment. If in doubt, stop

and obtain qualified help before proceeding.

General Safety Precautions

Before installing, operating or servicing this equipment, please read the following

precautions carefully:

Always disconnect electrical power before attempting maintenance for any electrical

or moving parts. Do not place hands, head, or any part of the body inside the

confines of the machine unless the mechanism is securely fastened and the

electrical supply is shut off.

Do not tamper with electrical wiring. Use only the specified power-supply cable. Use

only licensed electricians to check or repair electrical wiring.

In order to prevent damage to the machinery or injury to personnel, do not increase

the factory settings on either the electrical or mechanical overload safety devices.

Do not operate a machine if such modifications have been made.

Keep hands away from moving conveyors and moving parts. Conveyor belts that

have become worn or frayed can be hazardous and should be replaced promptly.

Never operate this or any moving equipment without all covers and guards in place.

The internal mechanism of most packaging machinery contains numerous shear,

pinch, and in-running nip points, many of which are capable of causing severe injury

and permanent disfiguration.

To minimize the potential for personal injury, always be sure that the machine

operators and others working on the machinery are properly trained in the correct

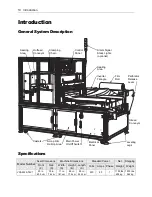

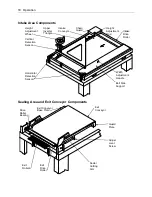

Summary of Contents for Value VSA2530TK-V1

Page 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Page 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Page 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Page 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Page 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Page 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Page 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Page 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Page 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Page 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Page 88: ......