LCR7000 & RHEOSIGHTS P/N: 974194 |

Rev: A

|

ECO: 52468

www.dynisco.com

From lab to production,

providing a window into the process

-66-

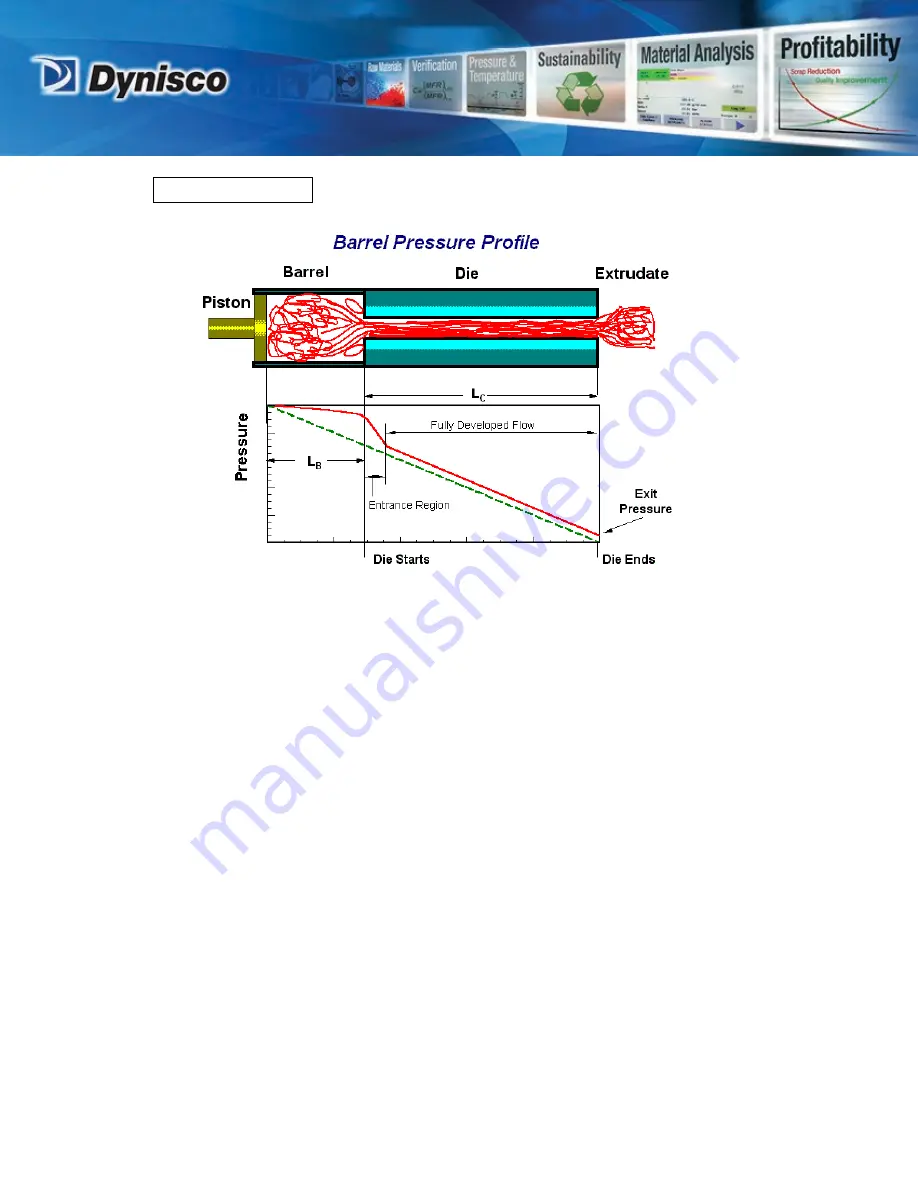

In the above diagram of the pressure vs. position it can be seen that, within the die the

pressure falls steeply as the exit is approached. Even within the barrel there is a small

pressure drop, known as the barrel pressure drop or barrel drag effect. Close to the die

entrance and just inside the die the pressure drop is quite steep as we force the material to

undergo a primarily extensional deformation to enter the die. Once past the entrance

region the pressure falls in a linear fashion as a result of the shearing action within the die.

(Note that the exit pressure is typically non-zero.) All of these pressure effects, the barrel

pressure drop, the entrance pressure drop, frictional effects and the exit pressure are all

part of the total pressure in addition to the pressure drop in the die. In the previous

equations we assumed that we were only measuring the pressure drop in the die. If we use

this assumption, we over-estimate the viscosity because of the extra pressures in the

system. We can correct for this by using several dies of the same diameter but differing

lengths and measuring the plunger force for a given shear rate at the same point in the

barrel for each die. These data are plotted as pressure verses the L/D of the dies for a series

of different shear rates and the lines extrapolated to L/D=0. The pressure at this point

represents the extraneous pressures, which can be subtracted so the true viscosity can be

calculated. (See the section Corrected Shear Stress.)

9.

Pressure Profile