change it according to the table shows.

Notes:

Don’t circumrotate the driven gear more than one circle, because it will violate the exact of

the examination.

3.Assembly

Assemble steps are opposite to the disassembly steps. Pay attention to the following requirements:

Notes:

Supply the initiative gear and the driven gear as a set

of groupware. Even if there only needs to change the

initiative gear or the driven gear, both parts should be

changed as a groupware.

Transmission bolts of the driven gear

Fix the driven gear in the bolts of the differential

Shell, which would bear cut stress, because the power in

the driven gear is transmitted to the differential shell

through bolts. Therefore, those specialized bolts should be made in chrome steel, not be replaced

by normal bolts.

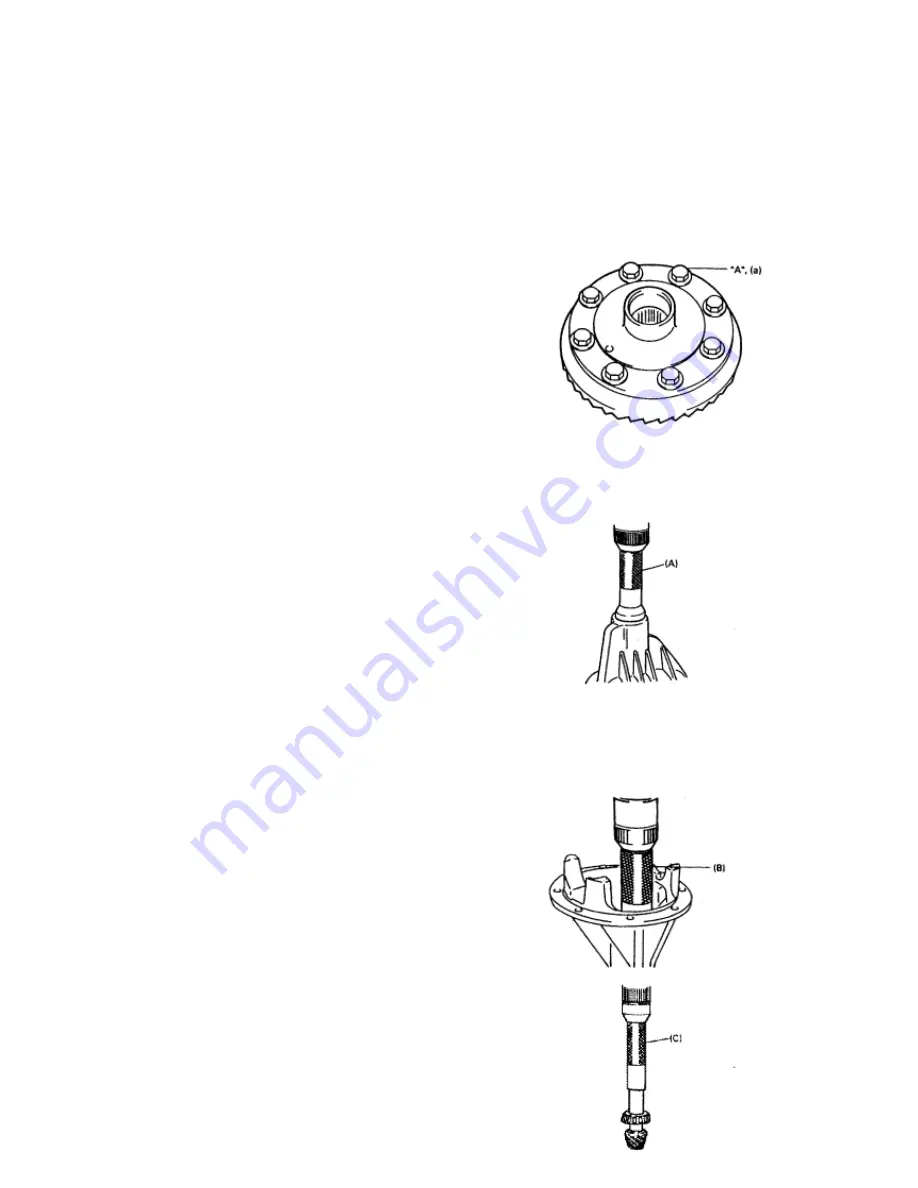

“A”

:

99000—32020

(a)

:

80

~

90 N·m

Gear bearing

Two roller bearings should be installed in the gear bearing,

outer seat circle installed in the final differential

shell and the inside seat circle installed in the gear

bearing.

1) the outside seat circle of the front bearing (fork) should be

installed by special implements:

Special Implements

(A)

:

09913-75520

1) the implements for installing the rear bearing ( gear side)

outside seat circle.

Special implements

(B)

:

09915—75510

3) The special implements for installing the

inner seat circle

.

Special Implements

(C)

:

09940—51710