function is to keep the pressure difference between oil distribution and suction manifold in a constant number. So

the fuel mass from oil atomizer is only determined by oil atomizer opening time, in order to control the

consistency of flammable mixture accurately.

2.

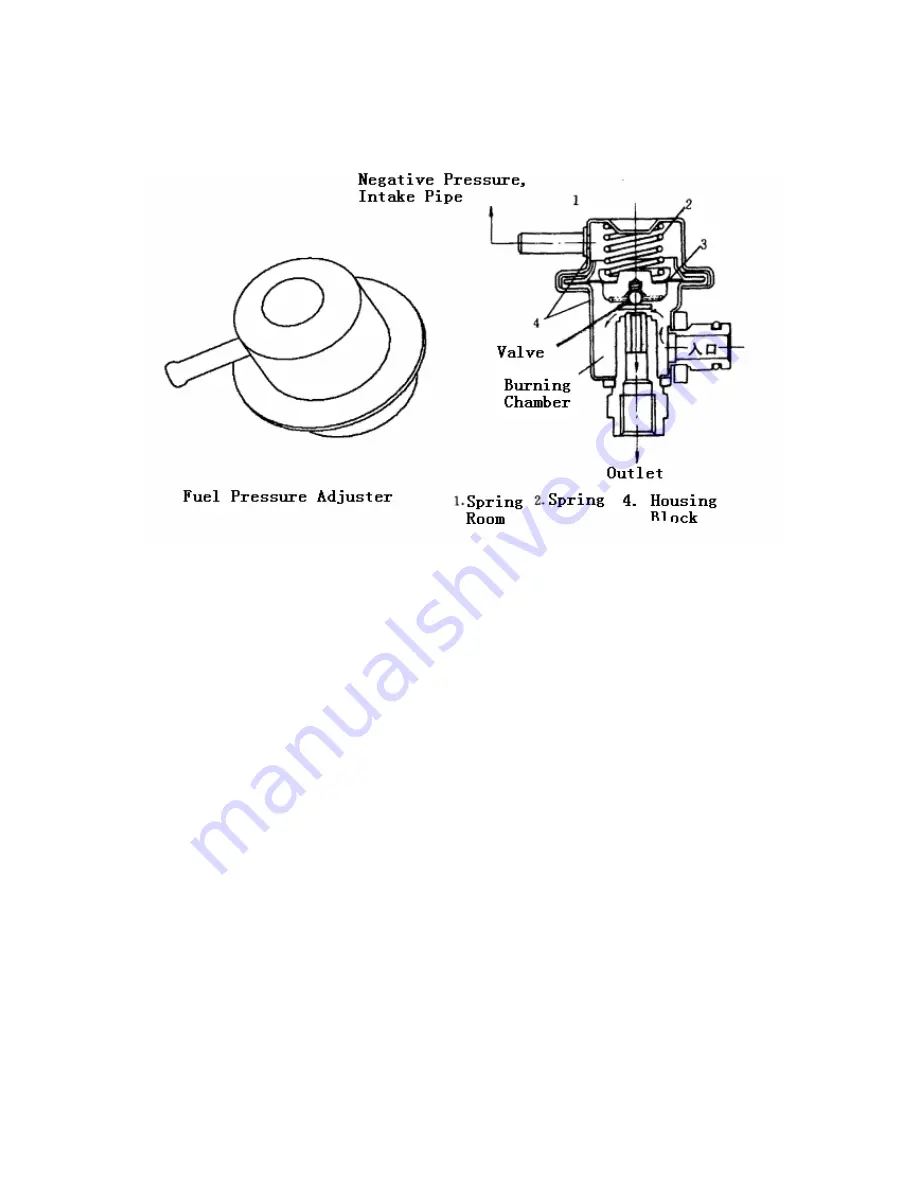

Like above picture showing, one flexible film which made of rubber and fiber make the oil regulator into

upper,down two chambers.Upper chamber trough the soft pipe lateral side connect with suction manifold, upper

chamer get spring inside.The down chamber is full of fuel which is throughed the fuel distribution outing from

pressure regulator bottom oil-in .Film bottom under the fuel pressure of fuel distribution pipe.,upper under the the

pressure of suction manifold and spring..Film can drive clack seat by twist ,let the valve open or close,because the

film deformation is small ,the acting force of spring can be considered no change. So the valve open and close is

mainly decided by the pressure difference between down chamber fuel pressure and upper chamber suction

manifold pressure.Assumption the valve is closed at the beginning,because of the reduction load of engine,suction

manifold pressure decrease; or fuel pressure goes up making the above pressure difference increase,ultimately the

film is jack-uped by fuel pressure,valve open,

Fuel through pressure regulator centre oil returen hole, comes back fuel tank,fuel pressure decrease,until valve

close. In this way, when engine working condiction change,the difference between fuel distribution pipe pressure

and suction manifold pressure may keep no change generally.

3. technical parameter

Fuel demands:

Fuel pressure regulator suits for the fuel which accord with People Republiic Of China Standard

GBl7930-1999<<motor lead-free petrol>> and National environment protect standard

GWKBl—1999<<motor petrol noxious substance control standard>>.

4. SYMPTOM AND JUDGEMENT

Symptom:

fuel pressure hypotony or hypertension, difficult to start.

Cause of Ordinary Symptom: Long term using without maintenance.:

1. filter clog;

2. Impurity particles to cause big leakage.

3. Machine damage artificially.

MAINTENANCE NOTE:During the maintenance