Page 17

At the end of each maintenance:

1. Restore product integrity and security settings

2. Clean carefully the adaptor

3. Close the oil caps if present

4. Restore all static seals, using the appropriate sealing

5. Perform all the steps required for commissioning the gear unit

LUBRICATION STATUS CHECK

Check the oil level on a monthly basis.

Replace the used oil with gear reducer still hot.

Before replacing the lubricant, make sure that the product has been stopped for about 30

minutes, sufficient time for the oil temperature to drop to levels which are not dangerous

for the operator.

Before introducing new oil, let some oil of the same type flow in order to remove particles

left inside the casing.

The new oil must be introduced being sure that there are no impurities present.

Check monthly that there are no lubricant leaks.

If the product remains inactive for a long time in an environment with a high percentage of

humidity (eg. with RH over 50%) fill it completely with oil. Of course at the time of subse-

quent commissioning it will be necessary to restore the level of lubricant.

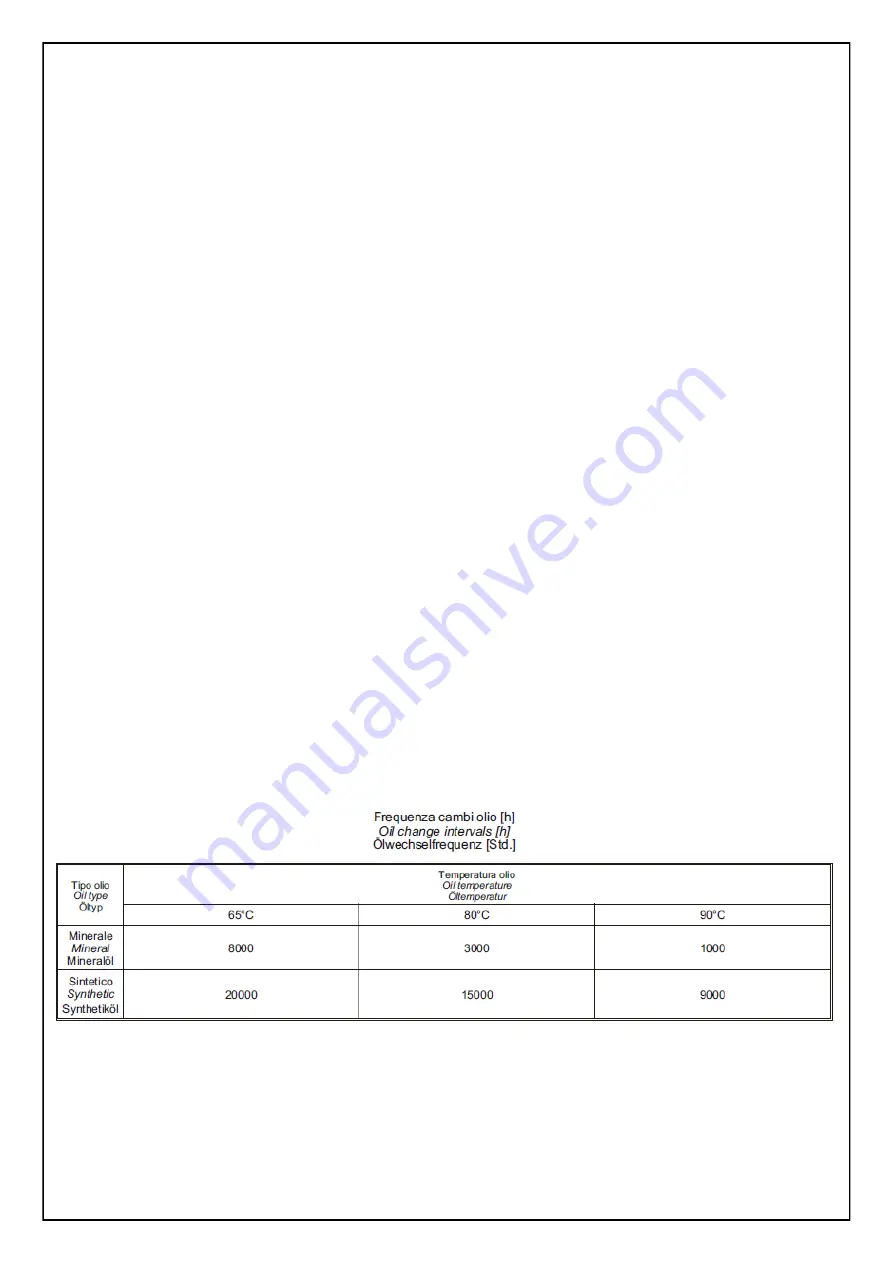

The table below shows the recommended lubricant replacement intervals, valid indicatively

in the absence of external pollution and overloads. More detailed information can be ob-

tained from your lubricant supplier, for example through periodic oil analysis.

Summary of Contents for SEPARATOR 2000

Page 23: ...Page 18...