TROUBLESHOOTING

USER MANUAL

91

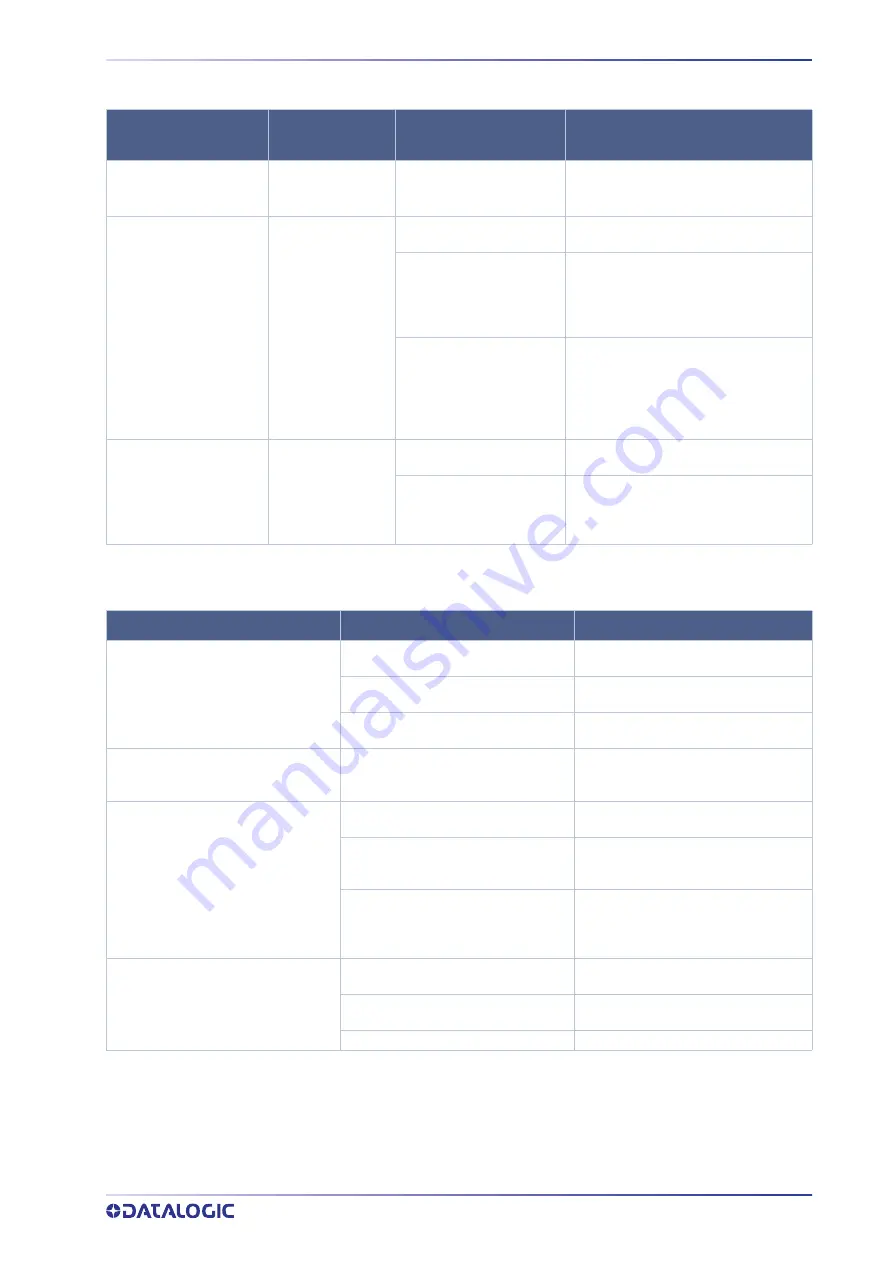

List of problems related to laser marker states

Blinking

GREEN

- Lighter™ Suite marking SW

corrupted

- C:\ or D:\ drive corrupted

Restore the laser marker (see “Recover the

system” on page 128)

Steady

ORANGE

Key Switch

selector in wrong

position

Check the

Key Switch

is set to

LASER ON

(see “Turning On sequence” on page 62)

EXT_ENABLE_A

and/or

EXT_ENABLE_B

contact are

LOW

level or disconnected

Check

X1.8

(

EXT_ENABLE_A

) and

X1.2

(

EXT_ENABLE_B

) input signals on the

X1 -

Command Box connector

are set to

HIGH

level (see “X1 - Command Box (Laser Con-

trol)” on page 33)

LASER_STOP

safety function

is active

Check

X3.13

(

/LASER_STOP_A

) and

X3.15

(

/LASER_STOP_B

) input signals on the

X3 -

SLO

connector are both closed to GND or

X3.12

(

LASER_STOP_A

) and

X3.14

(

LASER_STOP_B

) input signals on the

X3 -

SLO

connector are both closed to VCC

Steady

GREEN

Key Switch

selector in wrong

position

Check the

Key Switch

is set to

“1”

(see

“Turning On sequence” on page 62)

EXT_KEY

contact is

LOW

level

or disconnected

Check

X1.12

(

EXT_KEY

) input signal on the

X1 - Command Box

connector is set to

HIGH

level (see “X1 - Command Box (Laser Con-

trol)” on page 33)

List of most common problems

PROBLEM

DESCRIPTION

STATUS LED

POSSIBLE CAUSE

ACTION

Laser marker never goes to

WAIT FOR START state

Laser marker never goes to

READY state

Laser marker never goes to

STANDBY SHUTTER CLOSED

state

PROBLEM DESCRIPTION

POSSIBLE CAUSE

ACTION

Laser marker doesn't turn ON

POWER SUPPLY CABLE

cable discon-

nected

Check the

POWER SUPPLY CABLE

connec-

tion to the power grid

Power supply

SWITCH

of set to

OFF

Check that the

POWER SUPPLY

switch is

set to

ON

FUSES

damaged

Check that

FUSES

of power supply are not

damaged

Impossible to control the marking process

using the Command Box control signals

Incorrect integration

Check that the

X1 - Command Box

control

signals are compatible with the external

devices used for integration

Bad marking result

F-Theta

scan lens is dirty

Clean the

F-Theta

scan lens. See “F-Theta

scan lens cleaning procedure” on page 86

Incorrect focus distance

Check that the material to be marked is

placed at the right

working distance

. See

“Marking Area Specification” on page 26

Incorrect laser parameters

Check that the laser parameters set in the

layout are appropriate for the material to

be marked. Contact Datalogic Technical

Support

Laser marker doesn't engrave

Incorrect laser marker state

Check the laser marker state is set to

READY

F-Theta

lens protection not removed

Check that the

F-Theta

scan lens protec-

tion has been removed

The optical path is obstructed

Check that the optical path is free

Summary of Contents for AREX 401

Page 1: ...AREX 401 USER MANUAL InfraRed Fiber Laser Marker...

Page 113: ...SLO INTEGRATION EXAMPLE USER MANUAL 105 SLO INTEGRATION EXAMPLE...

Page 140: ...RECOVER THE LASER MARKER 132 AREX 401 Press FINISH to continue Press YES to continue...

Page 145: ...USER MANUAL 137 APPENDIX G MECHANICAL DRAWINGS...