Summary of Contents for DT-50

Page 57: ...DT 50 and DT 50A Tire Changer 57 P N 5900260 Rev A1 Dec 2020 Wiring Diagram...

Page 58: ...DT 50 and DT 50A Tire Changer 58 P N 5900260 Rev A1 Dec 2020 Labels...

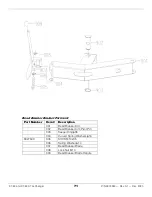

Page 60: ...DT 50 and DT 50A Tire Changer 60 P N 5900260 Rev A1 Dec 2020...

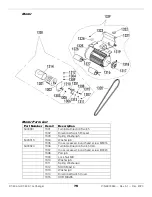

Page 73: ...DT 50 and DT 50A Tire Changer 73 P N 5900260 Rev A1 Dec 2020 Gearbox...

Page 83: ...DT 50 and DT 50A Tire Changer 83 P N 5900260 Rev A1 Dec 2020 Maintenance Log...

Page 84: ...1645 Lemonwood Drive Santa Paula CA 93060 USA 2020 Dannmar Inc All rights reserved Dannmar com...