Application guidelines

52

FRCC.PC.023.A7.22

Single compressors

Specific application recommendations

Low ambient start-up

Head pressure control under low

ambient conditions

Crankcase heaters

Under cold ambient conditions, upon start-up

the pressure in the condenser may be so low

that a sufficient pressure differential across

the expansion device cannot be developed to

properly feed the evaporator. As a result, the

compressor may go into abnormal low suction

pressure, which can lead to compressor failure.

Under no circumstances should the compressor

be allowed to operate under vacuum. The low-

pressure control must be set in accordance with

the table section “Pressure settings” in order to

prevent this from happening.

Low pressure differentials can also cause the

expansion device to “hunt” erratically, which

might cause surging conditions within the

evaporator, with liquid spillover into the

compressor. This effect is most pronounced

during low load conditions, which frequently

occur during low ambient conditions.

Several possible solutions are available to prevent

the compressor from drawing down to a vacuum

upon start-up under low ambient conditions.

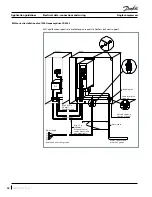

In air-cooled machines, cycling the fans with

a head pressure controller will ensure that the

fans remain off until the condensing pressure

has reached a satisfactory level. In water-cooled

units, the same can be performed using a water

regulator valve that is also operated by head

pressure, thereby ensuring that the water valve

does not open until the condensing pressure

reaches a satisfactory level.

Note: The minimum condensing pressure must

be set at the minimum saturated condensing

temperature shown in the application envelopes.

Under very low ambient conditions, in which

testing has revealed that the above procedures

might not ensure satisfactory condensing and

suction pressures, the use of a liquid receiver

with condenser and receiver pressure regulators

would be possible.

Condensing pressure control is also strongly

recommended to improve any system efficiency.

The most accurate value is to control the

condensing temperature at 12 K above the

ambient temperature for air cooled condensers.

For further information, please contact Danfoss

Technical support.

A crankcase heating will minimize refrigerant

migration caused by the large temperature

gradient between the compressor and the

remainder of the system. Refer to crankcase

heating section “Crankcase heating function” for

details and settings.

Low ambient compressor

operations

Low ambient operations and

minimum pressure differential

at steady running conditions

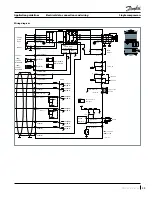

The VZH compressor requires a minimum

pressure differential of 87 to 101 psi between

the suction and discharge pressures to force the

orbiting scroll-down against the oil film on the

thrust bearing. Anything less than this differential

and the orbiting scroll can lift up, causing a

metal-to-metal contact. It is therefore necessary

to maintain sufficient discharge pressure in

order to ensure this pressure differential. Care

should be taken during low ambient operations

when heat removal from air-cooled condensers

is greatest and head pressure control may

be required for low ambient temperature

applications. Operation under low pressure

differential may be observed by a significant

increase in the sound power level generated by

the compressor.

Low load operations

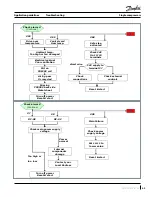

It is recommended that the unit be tested and

monitored at minimum load and, if possible,

during low ambient conditions as well. During

conditions of low load on the system, the

following considerations should be taken into

account to ensure proper system operating

characteristics.

The superheat setting of the expansion device

should be sufficient to ensure proper superheat

levels during low loading periods. 5 to 6 K stable

superheat is required. In addition, the refrigerant

charge should be sufficient to ensure proper

sub-cooling within the condenser so as to avoid

the risk of flashing in the liquid line before

the expansion device. The expansion device

should be sized to ensure proper control of the

refrigerant flow into the evaporator.