Application guidelines

63

FRCC.PC.023.A7.22

Single compressors

This minimum run time is set to guaranty long

enough running time at start up in order to

create enough refrigerant flow velocity in the

system to recover the oil to the compressor

sump.

• Current draw of compressor within acceptable

values (RLA ratings)

• No abnormal vibrations and noise.

Installation

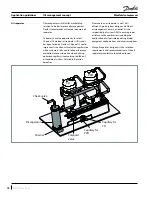

In installations with good oil return and line

runs up to 20 m, no additional oil is required. If

installation lines exceed 20 m, additional oil may

be needed. 4% of the total system refrigerant

charge (in kg) can be used to roughly define the

required oil top-up quantity (in liters) but in any

case the oil charge has to be adjusted based on

the oil level in the compressor sight glass. This

procedure must be conducted with the system

running at high load (compressor at full speed)

When the compressor is running under stabilized

conditions the oil level must be visible in the

sight glass.

The presence of foam filling in the sight glass

indicates large concentration of refrigerant in the

oil and / or presence of liquid returning to the

compressor.

Mandatory check is made at low load and

stabilised conditions, compressor at minimum

speed, for a minimum duration of 1 hour. The oil

level must be always visible at the compressor

sight glass. If any deviation is observed, this

means that some oil is trapped in the system,

heat exchangers and/or pipes.

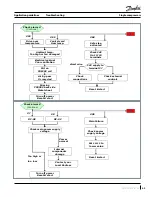

The CDS303 frequency converter integrates an

oil recovery management algorithm which needs

to be adjusted in regards to the system design.

Oil return management function forces the

compressor to rotate at 4200rpm (70 Hz) for an

adjustable given period of time in order to build

a good refrigerant gas velocity in the system to

allow the oil recovery to the compressor sump.

This oil management function is factory preset

with the following parameters:

• 28-10 Oil return management : enabled

• 28-11 Low speed running time : 60 minutes. This

is the duration during which the compressor

rotation speed is below 3000rpm (50 Hz)

• 28-12 Fixed boost interval : 24 hours

• 28-13 Boost duration : 30 seconds

If the oil level decreases down to the bottom

side of the sight glass, parameter 28-11 must

be adjusted to start the boost cycle. During this

boost cycle the oil level in the sight has to be

monitored in order to adjust the boost duration

on parameter 28-13 to a value that allows the oil

level to be recovered at ½ of the sight glass.

The oil level can also be checked a few minutes

after the compressor stops, the level must be

between ¼ and ¾ of sight glass.

When the compressor is off, the level in the

sight glass can be influenced by the presence of

refrigerant in the oil.

Always use original Danfoss POE oil 160SZ from

new cans.

Top-up the oil while the compressor is idle. Use

the schrader connector or any other accessible

connector on the compressor suction line and

a suitable pump. See News bulletin “Lubricants

filling in instructions for Danfoss Commercial

Compressors”.

Oil level checking and

top-up

Note this compressor is equipped with

a four poles electrical motor so the applied

frequency from the inverter will be 50 Hz for

25 rps (1500 rpm) up to 200 Hz for 100 rps

(6000 rpm).