Application guidelines

62

FRCC.PC.023.A7.22

Single compressors

Installation

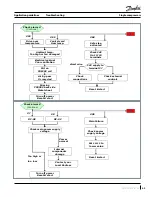

Leak detection

Leak detection must be carried out using a

mixture of nitrogen and refrigerant or nitrogen

and helium, as indicated in the table below.

Never use other gasses such as oxygen, dry air

or acetylene as these may form an inflammable

mixture.

Pressurize the system on HP side first then LP

side.

Leak detection

with refrigerant

Leak detection

with a mass spectrometer

Nitrogen & R410A

Nitrogen & Helium

Vacuum pump down and

moisture removal

Refrigerant charging

Moisture obstructs the proper functioning

of both the compressor and the refrigeration

system. Air and moisture reduce service life and

increase condensation pressure, which causes

abnormally high discharge temperatures that

are then capable of degrading the lubricating

properties of the oil. The risk of acid formation

is also increased by air and moisture, and this

condition can also lead to copper plating. All

these phenomena may cause both mechanical

and electrical compressor failures. The typical

method for avoiding such problems is a vacuum

pump-down executed with a vacuum pump, thus

creating a minimum vacuum of 500 microns (0.67

mbar). Please refer to News bulletin

Tl1-026-0302 “Vacuum pump down and

dehydration procedure”.

For the initial charge the compressor must not

run and eventual service valves must be closed.

Charge refrigerant as close as possible to the

nominal system charge before starting the

compressor. This initial charging operation must

be done in liquid phase as far away as possible

from the compressor. The best location is on the

liquid line between the condenser outlet and the

filter drier. Then during commissioning, when

needed, a complement of charge can be done

in liquid phase: slowly throttling liquid in on the

low pressure side as far away as possible from the

compressor suction connection. The refrigerant

charge quantity must be suitable for both

summer and winter operations.

Refer to news bulletin FRCC.EN.050 “Danfoss

Commercial Compressors recommended

refrigerant system charging practice” for more

details.

Loss of charge protection

Customer need to protect compressor against

loss of charge. Compared with fix speed

compressor, loss of charge could be more severe

to variable speed compressors. When loss of

charge occurs, variable speed compressors will

speed up to compensate capacity reduction,

Further drive will active derating function to

slow compressor heating up. Thus compressors

will run longer time at high temperature but

low oil viscosity than fixed speed and will lead

to compressor damage eventually. Low pressure

switch and discharge gas thermostat could

protect loss of charge somehow. But it is highly

recommended to protect compressor from high

superheat.

Commissioning

The system must be monitored after initial

startup for a minimum of 60 minutes to ensure

proper operating characteristics such as:

• Proper metering device operation and desired

superheat readings

• Suction and discharge pressure are within

acceptable levels

• Correct oil level in compressor sump indicating

proper oil return

• Low foaming in sight glass and compressor

sump temperature 10K above saturation

temperature to show that there is no refrigerant

migration taking place

• Acceptable cycling rate of compressors,

including duration of run times.

A short cycling protection is provided in the

CDS303 frequency converter. It is factory preset

“enabled” with the following parameters in:

28.01 - interval between 2 starts: 300 secondes

28.02 - minimum run time: 12 seconds.