Application guidelines

45

FRCC.PC.023.A7.22

Single compressors

Operating conditions

Insufficient oil level can be the result of oil

depositing itself in pipes and heat exchangers.

The oil deposit can be returned to the crankcase,

by increasing velocity for short periods, at regular

time intervals or when velocity is too low to

ensure adequate oil returns.

With oil return management these two oil return

mechanisms can be programmed in the CDS303.

With oil return management function enabled,

the CDS303 performs oil return by boosting the

compressor speed to 4200 rpm (70 rps) for a

selectable duration as programmed in parameter

28.13. The boosts are performed at fixed time

intervals (as programmed in parameter 28.12)

or if the compressor speed has been less than

3000 rpm (50 rps) for too long (as programmed in

28.11) whichever occurs first. Thus the maximum

time between two consecutive oil return boosts

is programmed in 28.12.

Considering oil return risk, split system with

more than 10m piping length need mandatory

application approval by Danfoss application

specialists.

Use the accessory “oil level switch” with the

appropriate compressor housing having the

fitting pre assembled and refer to "VZH hybrid

manifolding" section at the end of this document.

Oil return management

function (single compressor)

Oil return management in

hybrid manifolding

The discharge gas temperature must not exceed

275°F.

A discharge gas temperature protection device

must be installed on all heat pumps. In reversible

air-to-air and air-to-water heat pumps the

discharge temperature must be monitored

during development test by the equipment

manufacturer.

The compressor must not be allowed to cycle

on the discharge gas thermostat. Continuous

operations beyond the compressor’s operating

range will cause serious damage to the

compressor!

A DGT accessory is available from Danfoss: refer

to accessories pages at the end of this document.

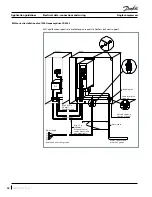

The discharge gas thermostat accessory kit (code

no.7750009) includes all components required

for installation, as shown below. The thermostat

must be attached to the discharge line within

5.91 inch from the compressor discharge port

and must be thermally insulated and tightly fixed

on the pipe.

Discharge line

Insulation

Bracket

Thermostat

ID

Name

Factory

Setup

"long pipe

(25-30m)"

Unit

2810 Oil Return

Management

On

On

2811 Low Speed Running

Time

60

30

min

2812 Fixed Boost Interval

24

6

h

2813 Boost Duration

30

60

s

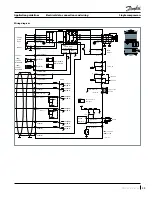

High and low pressure

protection

High pressure

According to EN378-2, a high-pressure (HP) safety

switch is required to shut down the compressor.

The high-pressure switch can be set to lower

values depending on the application and

ambient conditions. The HP switch must either be

placed in a lockout circuit or consist of a manual

reset device to prevent cycling around the high-

pressure limit. If a discharge valve is used, the HP

switch must be connected to the service valve

gauge port, which must not be isolated. The HP

switch must be connected to the CDS303 input

37 or an external contactor placed between the

drive and the compressor.