Application guidelines

83

FRCC.PC.023.A7.22

Manifold compressors

Installation and service

Handling

Compressor mounting

Tightening torques

Installation and service procedures for a parallel

system are similar to basic system installations.

The selection of additional system components

for parallel installations follows the basic system

common rules. Please refer to the Application

Guidelines for Danfoss SH scroll compressors

(FRCC.PC.007) for detailed installation and service

procedures.

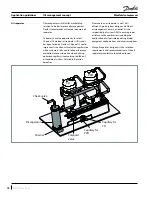

Danfoss Commercial Compressors recommends

using the lift and handling devices, as shown in

picture beside, and that the following procedure

be used to prevent damage.

• Two lift rings are provided on each compressor.

Use all four rings.

• Maximum loads authorized per sling and for the

hoist hook must not be lower than the weight

of the assembly.

• The minimum spreader bar length must be at

least equal to the centre distance between the

two compressors to prevent bending the frame.

• When lifting, use a spreader block between the

compressors to prevent any unit frame damage.

• When the tandem unit is already mounted

into an installation, never lift the complete

installation by using the lift rings on the

compressors.

For VZH tandem systems, Danfoss supply both

rigid and rubber connections, but only rubber

connection is recommended by Danfoss. For

customers who prefer to configure compressor

lay out on their own, they could also get rigid

mounting components.

Regarding rubber connection, compressors

are mounted on the base with enough stiff by

grommets. To have enough stiffness, compressors

could be mounted on the rails then fix the rails to

a frame. Or compressors with rubber connection

could be mounted on the frame directly.

Spreader block

Spreader bar

Slings

Frame

Rubber connection

VZH compressors come delivered with four

rubber mounting grommets and metal sleeve

liners that serve to isolate the compressor

from the base frame. The grommets must

be compressed until contact between the

flat washer and the steel mounting sleeve is

established. The grommets attenuate to a great

extent the transmission of compressor vibrations

to the base frame.

0.59 inch

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

The required bolt size for VZH170 hybrid

compressors is HM8-55 and must be tightened to

a torque of 21Nm.

HM 8 bolt

Lock washer

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

1.10 inch

Compressor

base plate

The required bolt size for the VZH088 & 117

hybrid compressors is HM8-40. This bolt must be

tightened to a torque of 15 Nm.

Base plate, rails, etc. with enough rigidity