Application guidelines

54

FRCC.PC.023.A7.22

Single compressors

Specific application recommendations

Discharge line and reversing

valve

Defrost and reverse cycle

The VZH scroll compressor is a high volumetric

machine and, as such, can rapidly build up

pressure in the discharge line if gas in the line

becomes obstructed even for a very short period

of time which situation may occur with slow-

acting, reversing valves in heat pumps. Discharge

pressures exceeding the operating envelope may

result in nuisance high-pressure switch cutouts

and can generate excessive load on bearings and

motor.

To prevent such occurrences, it is important

that a 3.28 ft minimum discharge line length be

allowed between the compressor discharge port

and the reversing valve or any other restriction.

This gives sufficient free volume for the discharge

gas to collect and to reduce the pressure peak

during the time it takes for the valve to change

position. At the same time, it is important that

the selection and sizing of the reversing or 4-way

valve ensure that the valve switches quickly

enough to prevent against too high discharge

pressure and nuisance high-pressure cutouts.

Check with the valve manufacturer for optimal

sizing and recommended mounting positions.

It is strongly recommended to reduce the

compressor speed to 25/30 rps before the 4-way

valve is moved from a position to another.

Refer also to high and low pressure protection.

After the 4-way valve is moved to defrost

position, and in order to shorten the defrost

period, the compressor speed can be maintained

at 70 rps during the defrost period.

When the compressor is started again, after

defrost, it will run at 25/30 rps for a 10 seconds

period. After this period it is recommended to

maintain the speed at 50 rps for 10 to 15 seconds.

Thus to avoid excessive liquid refrigerant to come

back to the compressor sump.

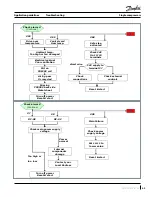

Defrost cycle logic

Start of defrost

sequence

End of defrost

sequence

Compressor on

Compressor off

4 way valve position 1

4 way valve position 2

10" 2"

10" 2"

In order to limit liquid amount handled by

the compressor when beginning & ending

defrost,below defrost cycle logic is suggested:

- stop the compressor before moving the 4 way

valve:

step 1: stop the compressor

step 2: wait for 10 seconds

step 3: move the 4 way valve

step 4: wait for 2 seconds

step 5: restart the compressor

Defrost cycle logic must respect all system

components recommendations, in particular 4

way valve Max. Operating Pressure Differential.

EXV can also be opened when the compressor is

stopped and before 4 way valve is moving in

order to decrease pressure difference. Opening

degree and time have to be set in order to keep a

minimum pressure for 4 way valve moving.

Danfoss recommend above defrost cycle logic,

but the control logic is also system specified.