Application guidelines

37

FRCC.PC.023.A7.22

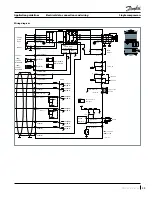

Single compressors

Electrical data, connections and wiring

Wiring & EMC protection

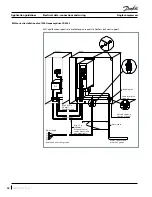

The motor compressor power supply from

the CDS303 frequency converter to the VZH

compressor must be done with a braided

screened / armored cable. This cable needs to

have its screen / armor conduit connected to

earth on both ends. Avoid terminating this cable

connection with twisting ends (pigtails) because

that would result in an antenna phenomena and

decrease the effectiveness of the cable.

Control cables to the CDS303 frequency

converter must use the same installation

principles as the power supply cable.

The motor compressor cable must be installed in

a conduit separated from the control and mains

cables.

Physical installation of the frequency converter

on the mounting plate must ensure good

electrical contact between the mounting plate

and the metal chassis of the converter. Use star-

washers and galvanically conductive installation

plates to secure good electrical connections.

Refer to instructions MG34M302 for tightening

torques and screw sizes.

Note that the CDS303 must be mounted on a

plain wall to ensure a good air flow through its

heat exchanger.

From network to frequency converter

From frequency converter to compressor

Type

in²

AWG

Type

in²

AWG

200 - 240 V

CDS-15kW

0.04

4

VZH088-J

0.04

4

CDS-18.5 kW

0.05

2

VZH117-J

0.05

2

CDS-22 kW

0.08

1

VZH170-J

0.08

1

380 - 400 V

CDS-15 kW

0.009

10

VZH088-G

0.009

10

CDS-18.5 Kw

0.015

8

VZH117-G

0.015

8

CDS-22 kW

0.025

6

VZH170-G

0.025

6

525 - 600 V

CDS-18.5 kW (IP20)

0.015

8

VZH088-H

0.009

10

CDS-30kW (IP20)

0.04

4

VZH117-H

0.015

8

CDS-30kW (IP20)

0.04

4

VZH170H

0.025

6

Wire sizes

Below table lists recommended wiring sizes for the motor compressor power supply cables. These

wiring sizes are valid for a cable length up to 65 ft.

from network

to drive

from drive to

to compressor