1. HEALTH AND SAFETY

This concerns the hazards, which may be encountered

when installing and maintaining this equipment. It is

therefore important that these instructions are followed.

1

Before installation

Ensure that:

a) the voltage, working fluid and the maximum working

pressure stated on the product nameplate is suitable for

the working environment.

b) the proposed method of mounting is adequate to

support the total operational weight of the unit.

During installation and maintenance

Ensure that:

a)

the unit is installed and maintained by qualified

personnel only.

b) the electrical supply is isolated and secured from

accidental re-connection.

c) the working area is adequately ventilated.

d) the temperature of coils with vinyl coated fins does

not exceed 150°C (e.g. during brazing) as toxic

fumes would be produced.

2. INSTALLATION

General

Upon receipt, the units should be visually inspected and

the supplier notified (within seven days) of any damage

or shortages. Units are not portable and are only for

permanent installation. Electrical screw terminals in

control panels and motor mountings should be checked

for security.

Location

To ensure optimum performance, the condensing unit

should be situated to give uniform air distribution across

the coil. Obstructions to airflow should be minimised.

Coils should ideally be shaded from the sun.

Consideration should also be given to servicing

requirements - there should be at least 600mm

clearance on the right hand side of the units, and access

panels must be clear of obstruction.

Floor/Roof Mounting

When Floor Mounted a gap of 250mm

must

be left

between the rear of the unit and the nearest wall.

Fixing holes are provided in the feet for securing the

condensing unit to a plinth. If the condensing unit is roof

mounted, it is recommended that isolation material be

used between the feet of the unit and the roof itself.

Guarding Cages

Floor mounted guard cages are available for individual

units where additional protection to the installation may

be required (contact your supplier for further details).

Pipework

Pipework to and from the unit should be selected to suit

the application and not the connection size of the unit. It

should be supported independently from the unit and in

a way that prevents the transmission of vibration to the

unit. A competent engineer should install refrigerant

pipework to a high standard of refrigeration practice.

Electrical

Electrical components are located in an enclosure,

situated on the front RH side of the unit and behind a lift-

off service panel. Always ensure that the electrical

supply to the unit is isolated before removing this panel.

All electrical components are tested during the

manufacturing process.

The electrical supply to the unit must be taken from a

correctly sized (and motor rated) main circuit breaker or

fuse box, corresponding to the current shown on the

unit's nameplate.

Function of Controls

(Please refer to the relevant wiring diagram in Sect. 10)

a) Unit isolation

- is situated behind a swivel plate

cover on the main control box cover.

b) HP/LP

- The HP switch is to prevent overpressure

within the system. It should only operate under fault

conditions. The LP switch is to prevent too low a

pressure. Pressure switches should be set to the

required operating limits during commissioning. Do not

adjust these switches outside of the acceptable

operating limits, (see section 4).

c) FSC

- The fan speed controller is used to control the

unit's head pressure under low ambient conditions. As

the ambient temperature falls the fan speed is reduced

to maintain head pressure.

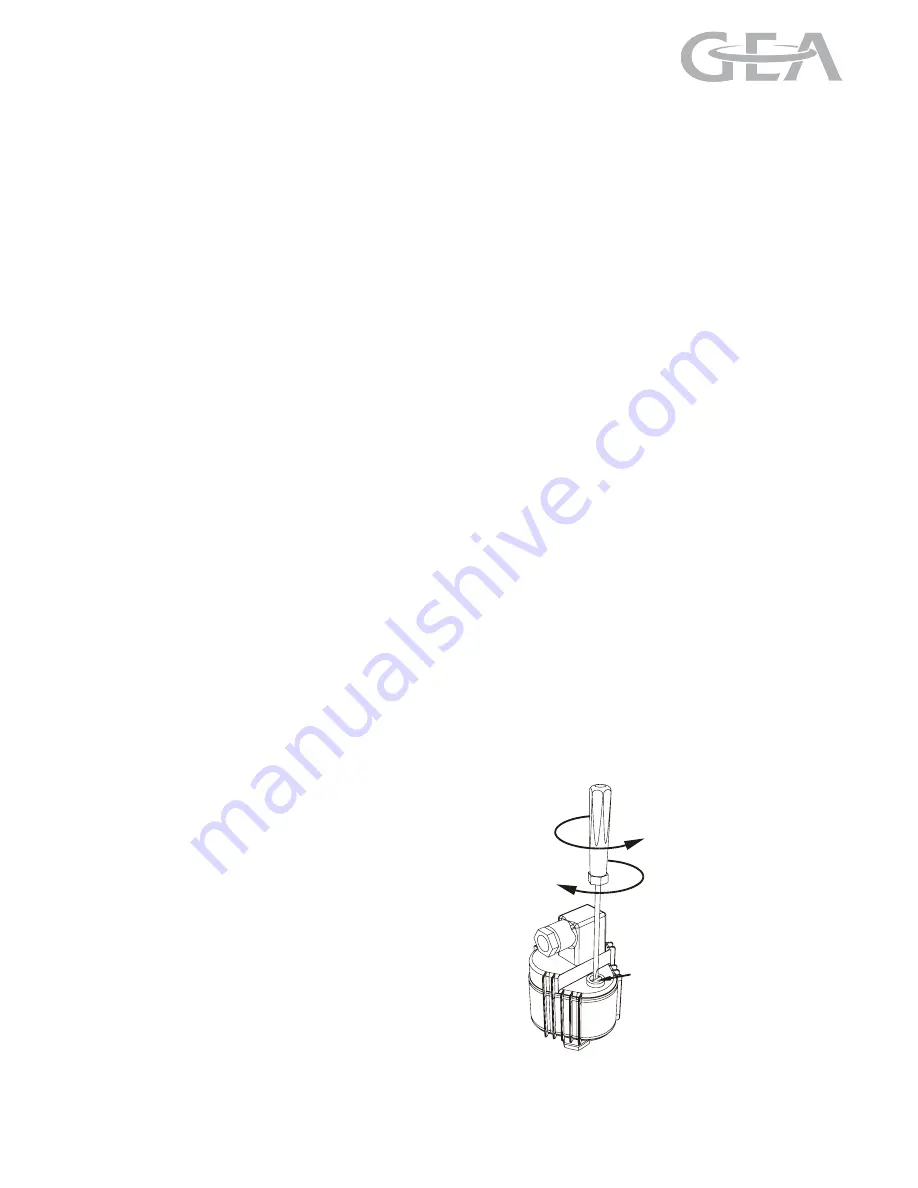

Adjustment of FSC – Control Point (2 Fan Units)

The Fan Speed Controller is fitted on the rear port of the

receiver outlet valve, and is factory set to maintain 39°C

(17 barg R404A), if the desired Mid point differs from the

factory setting it can be adjusted as follows:

A n ti-C lo ckw ise

R e d u c e S e tp o in t

C lo ckw ise

In cre a se S e tp o in t

A d ju stm e n t

S c re w

Adjustment of FSC – Control Point (4 Fan Units)

The Fan Speed Controller is fitted on the control panel

RH side, and uses a pressure sensor module mounted

on the rear port of the receiver outlet valve, and is

factory set to maintain 36.5°C (15.5 barg R404A). If the

operating pressure falls below this setpoint the fans will

Searle NSQ NSE NCQ

NCE NDQ SCQ

Installation and Maintenance Instructions

ENGLISH

Summary of Contents for Searle NSQ Series

Page 10: ...11a SCQ All Units 1MX A SCQ 611 06 XXX W Single Phase with AC Fans 10...

Page 11: ...11b SCQ All Units 3MX A SCQ 613 06 XXX W Three Phase with AC Fans 11...

Page 14: ...11e NSQ NSE15 1MX A 44 611 16 XXX W ZB15 Single Phase with AC Fans 14...

Page 16: ...11g NSQ NSE19 to 26 1MX A B or C 44 611 06 XXX W ZB19 to ZB26 Single Phase AC Fans 16...

Page 18: ...11i NSQ NSE15 to 45 3MX A B C 44 613 06 XXX W ZB15 to ZB45 Three Phase AC Fans 18...

Page 20: ...11k NDQ 30 to 45 3MX S C 44 613 XDX W ZBD30 to ZBD45 Three Phase AC Fans 20...

Page 21: ...11l NCQ NCE 56 to 110 3MX S D E 2 3 44 633 16 XXX W ZB56 to ZB11 Three Phase AC Fans 21...

Page 22: ...11m NSQ NSE 15 to 30 1MX S A B C 2 3 44 611 ST2 Layout Diagram 22...

Page 23: ...11n NSQ NSE 09 to 18 3LX S 15 to 45 3MX S A B C 2 3 44 613 ST2 Layout Diagram 23...

Page 24: ...11o NCQ NCE 24 to 48 3LX S 56 to 110 3MX S D E 2 3 44 633 3 ST2 Layout Diagram 24...

Page 25: ...12 DIMENSIONS Case A B C 25...