3

/1 parameter. (Action only valid when parameter H2 = 3)

maximum limit (Not Applicable).

‘lP’ Low pressure alarm

Special Functions:

Controller 1: suction pressure lower than the minimum

limit

The Special Functions can be activated by:

Controller 2: condensing pressure lower than the

minimum limit

‘d1’ Discharge temperature alarm

Digital scroll only: Discharge end temperature is too high

‘EP’ Error pressure

Controller 1: suction pressure sensor failure

Controller 2: condensing pressure sensor failure (N/A)

‘Fr’ Fast recovery alarm

Controller 1: fast recovery from low suction pressure

Controller 2: fast recovery from low condensing pressure

(N/A)

‘hr' High discharge pressure alarm

Controller 1: high discharge pressure recovery

Controller 2: high discharge pressure recovery (N/A)

‘

rE’ Emergency run

Controller 1: runs with c6 numbers of compressors

Controller 2: runs with c6 numbers of fans (N/A)

‘E1’ Feedback alarm 1

Controller 1: digital input associated with compressor 1

has changed into alarm state (safety chain)

Controller 2: digital input associated with fan(s) has

changed into alarm state (safety chain) (N/A)

‘E2’ Feedback alarm 2

Controller 1: digital input associated with compressor 2

has changed into alarm state (safety chain) (N/A)

‘n1’ Service alarm 1

Controller 1: compressor 1 operating time higher than

run limit (A9)

Controller 2: fan operating time higher than run limit (A9)

(N/A)

‘n2’ Service alarm 2

Controller 1: compressor 2 operating time higher than

run limit (A9)

Er Data error

Data send to the display is out of range

Messages

‘---‘ No data to display

The display will show an “---” at node start up and when

no data is send to the display.

‘In’ Reset to default values activated

The display will show an “In” when the factory default

configuration data set

is initialized.

‘Id’ Wink request received

The display will show a flashing “Id” when the wink

request was received. The flashing “Id” will be shown on

the display until the service button will be pressed, or a

30 min delay timer will expire or a second wink request

is received. This function is action only when using

SNMP protocol. The node is offline and no application is

running. This is the result of a network management

command and will happen for example during node

installation.

WARNING: Do not set the controller outside of the

application limits as shown in section 4.

For a full description of controller settings please refer to

the table on page 8.

g) Anti-Cycle & Delay Start Timer – Standard on

NSQ/NCQ, optional on NSE NCE, with electrical options

W & T.

Anti-Cycle Function

Units are fitted with a compressor Anti-Cycle and Delay

Start timer. This timer will prevent rapid repeated

starting of the compressor, by enforcing a maximum of

10 compressor starts per hour. The timer runs from Start

to Start, therefore if the compressor has run for more

than 6 minutes it will be allowed to start again

1. Press

and

together for more than 5

seconds. A flashing 0 is displayed.

2. Press

or

until the password is displayed

(default = 12). If password was changed, select the new

password.

3. Press

to confirm password , A 0 is displayed and

the Special Function mode is activated.

4. Press

or

to select the function. The number

of special functions is dynamic and controller

dependent. See list below.

5. Press

to activate the function without leaving the

special function mode.

6. Press

to activate the function and leave the

special function mode.

Most of the Special Functions work in a toggle mode,

the first call activates the function, and the

second call

deactivates the function.

The indication of the function can only be

displayed after exiting the special function mode.

• 0: Display test function

• 1: Displays the current TCP/IP address

• 2: Set the controller TCP/IP address to the default

value: 192.168.1.101

• 3: Resets all parameters to the factory default setting.

The controller will indicate “oF” during the reset.

The data to be shown on the display can be selected by

the user. In case of an alarm, the alarm code is

displayed alternately with the selected data. The user

can inhibit the alarm code. Press the

button to scroll

through all possible displayable data.

The display will show for one second the numerical

identifier of the data and then the selected data. After

two minutes the display will return to the by parameter /1

selected data.

Indications On The Display:

Compressor Controller

• State

• Alarm in combination with alarm message and alarm

LED

• Suction pressure or saturation temperature from

suction pressure

• Parameter

Other display

• Pressure: Pressure value in bar (g)

• Alarm: Alarm condition

• IR: IR communication enabled

Alarm Codes

‘HP’ High pressure alarm

Controller 1: suction pressure higher than the maximum

limit

Controller 2: condensing pressure higher than the

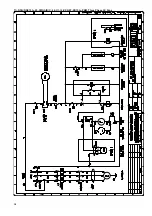

Summary of Contents for Searle NSQ Series

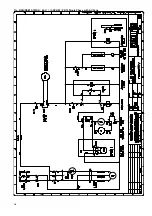

Page 10: ...11a SCQ All Units 1MX A SCQ 611 06 XXX W Single Phase with AC Fans 10...

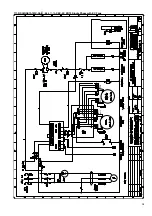

Page 11: ...11b SCQ All Units 3MX A SCQ 613 06 XXX W Three Phase with AC Fans 11...

Page 14: ...11e NSQ NSE15 1MX A 44 611 16 XXX W ZB15 Single Phase with AC Fans 14...

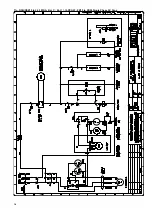

Page 16: ...11g NSQ NSE19 to 26 1MX A B or C 44 611 06 XXX W ZB19 to ZB26 Single Phase AC Fans 16...

Page 18: ...11i NSQ NSE15 to 45 3MX A B C 44 613 06 XXX W ZB15 to ZB45 Three Phase AC Fans 18...

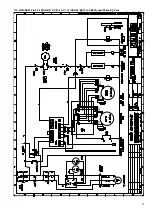

Page 20: ...11k NDQ 30 to 45 3MX S C 44 613 XDX W ZBD30 to ZBD45 Three Phase AC Fans 20...

Page 21: ...11l NCQ NCE 56 to 110 3MX S D E 2 3 44 633 16 XXX W ZB56 to ZB11 Three Phase AC Fans 21...

Page 22: ...11m NSQ NSE 15 to 30 1MX S A B C 2 3 44 611 ST2 Layout Diagram 22...

Page 23: ...11n NSQ NSE 09 to 18 3LX S 15 to 45 3MX S A B C 2 3 44 613 ST2 Layout Diagram 23...

Page 24: ...11o NCQ NCE 24 to 48 3LX S 56 to 110 3MX S D E 2 3 44 633 3 ST2 Layout Diagram 24...

Page 25: ...12 DIMENSIONS Case A B C 25...