Application guidelines

9

FRCC.PC.023.A7.22

Single compressors

Technical specifications

Compressor specifications

Frequency converter

specifications

Compressor model

Swept

volume

(cu.in/rev)

Displacement

Oil charge

(oz)

Net weight

(lbs)

25 rps

(cu.ft/h)

50 rps

(cu.ft/h)

60 rps

(cu.ft/h)

100 rps

(cu.ft/h)

VZH088

5.39

272

544

657

1088

112

121

VZH117

7.13

357

717

869

1434

122

134

VZH170

10.39

523

1045

1261

1914

228

247

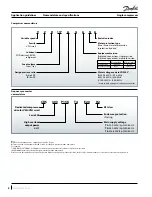

Mains supply voltage

T2: 200 - 240 V +/-10% (3-phase)

T4: 380 - 480 V +/-10% (3-phase)

T6: 525 - 600 V +/-10% (3-phase)

Supply frequency

50 / 60 Hz

Output voltage

0 - 100 % of supply voltage

Inputs

6 digital (0 - 24 V), 2 analogue (0 /±10 V or 4 - 20 mA, scalable)

Programmable outputs

2 digital (0- 24 V), 1 analogue (0-24 V), 2 relay

Protection functions

Over-current protection, low / high current handling

Compressor functions

Discharge gas temperature protection, pressostat / thermostat function, short

cycle protection, oil return management

Oil injection control

Bearings lubrication

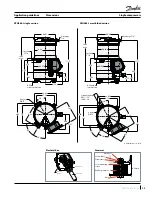

VZH compressors are equipped with an oil

injection system that makes the compression

pockets more tight thus improving the isotropic

efficiency of the compressor as well as controls

the oil circulation ratio, at all running speeds.

The frequency converter via an oil injection valve

controls this system. The oil injection valve is a

normally closed valve. At low speed, the valve

is closed and the oil is injected to the scroll set

suction ports.

The compressors are delivered with no coils.

208V-240V or 24V coils are available as accessory

(refer to “Accessories” section). The coil must be

installed for oil injection control.

Control parameters are factory preset but

accessible on the parameter list as read only

values.

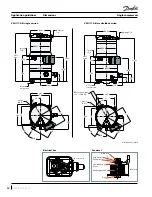

Optimal bearings lubrication is ensured by a

gearotor oil pump at all compressor speeds.