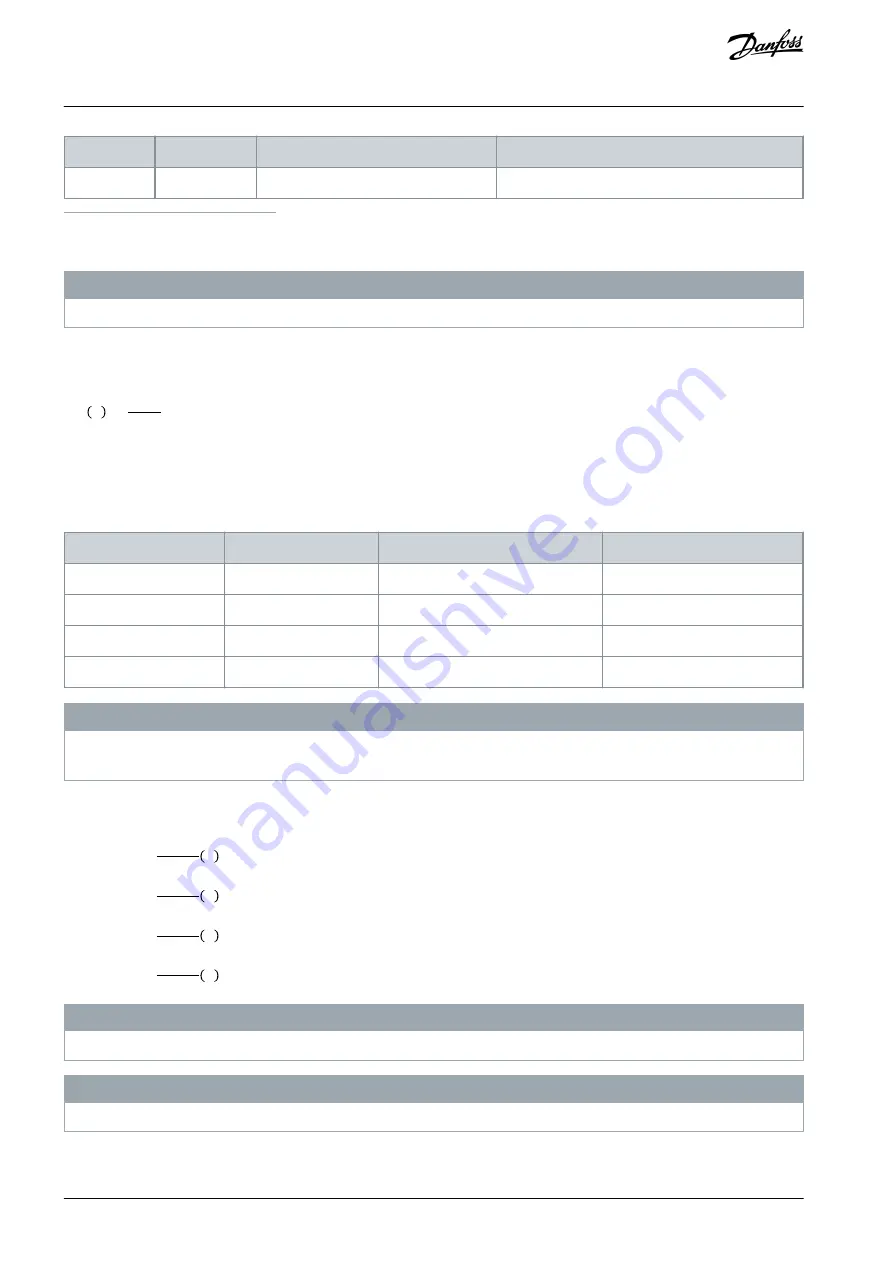

Cycle time (s)

Braking duty cycle at 100% torque

Braking duty cycle at overtorque (150/160%)

P630–P1M0

600

40%

10%

1

500 kW at 86% braking torque/560 kW at 76% brake power.

2

500 kW at 130% braking torque/560 kW at 115% brake power.

N O T I C E

Ensure that the resistor is designed to handle the required braking time.

The maximum allowed load on the brake resistor is stated as a peak power at a given intermittent duty cycle and can be calculated

as:

R

br

Ω =

Udc

2

Ppeak

where

P

peak

=P

motor

x M

br

[%]xη

motor

xη

VLT

[W]

The brake resistance depends on the DC-link voltage (U

dc)

.

Table 88: DC-link Voltage (UDC), FC 202

Size [V]

Brake active [V DC]

High-voltage warning [V DC]

Overvoltage alarm [V DC]

FC 202, 3x200–240 V

390

405

410

FC 202, 3x380–480 V

778

810

820

FC 202, 3x525–600 V

943

965

975

FC 202, 3x525–690 V

1099

1109

1130

N O T I C E

For use of 3

rd

party brake resistors, make sure to comply with the table above. The VLT® Brake Resistor MCE 101 series is optimized

for Danfoss VLT® series drives.

Danfoss recommends a brake resistance R

rec

that can guarantee that the drive can brake at the highest brake power (M

br(%)

) of

150%. The formula can be written as:

200 V: Rrec =

107780

Pmotor

Ω

500 V: Rrec =

464923

Pmotor

Ω

600 V: Rrec =

630137

Pmotor

Ω

690 V: Rrec =

832664

Pmotor

Ω

N O T I C E

The brake resistor circuit resistance selected should not be lower than what Danfoss recommends respecting the current limits.

N O T I C E

If a higher value is selected, the brake energy is reduced accordingly to a value below 150%.

AJ300847815559en-000101 / 130R0337

140 | Danfoss A/S © 2020.09

Electrical Installation

Considerations

VLT® AQUA Drive FC 202

Design Guide