•

•

-

-

-

-

-

-

•

•

•

•

•

•

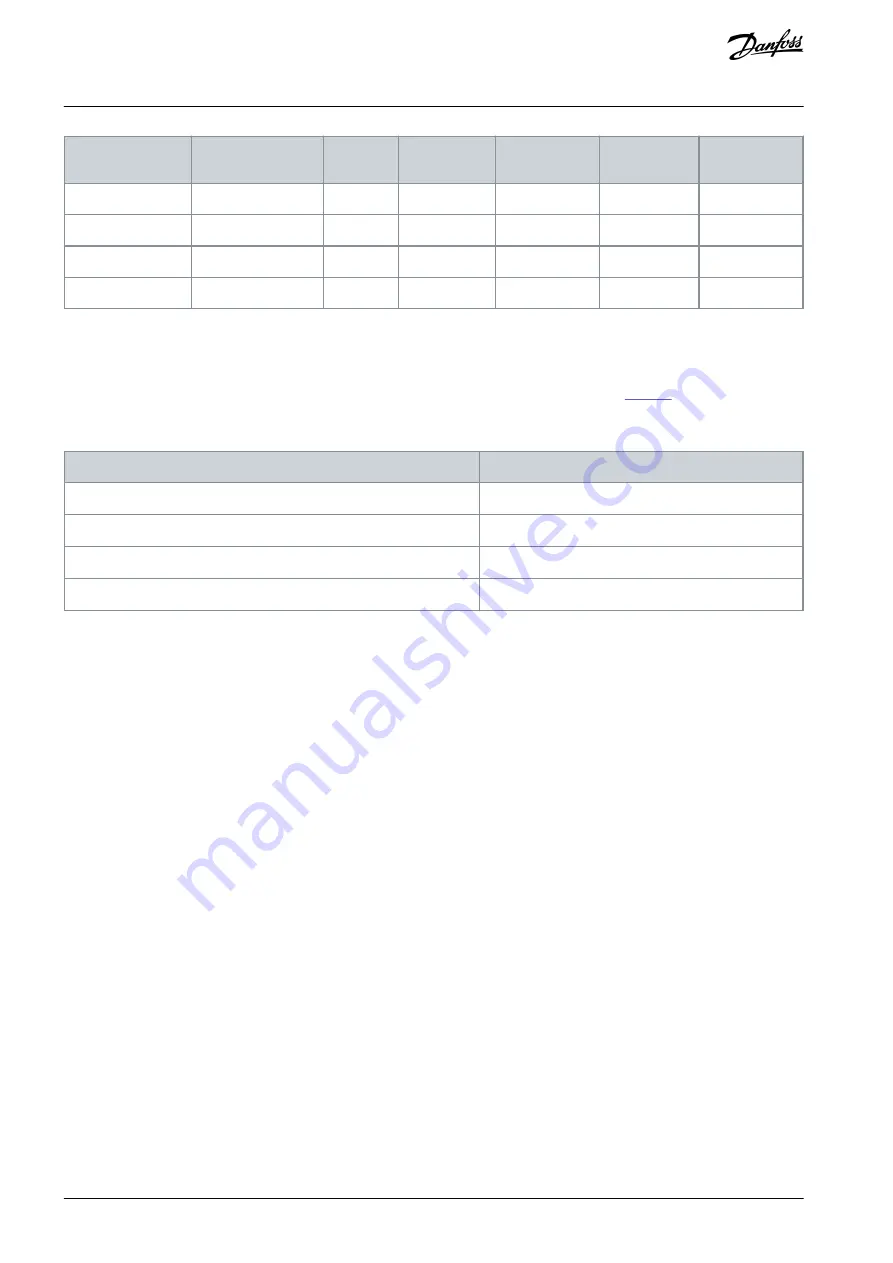

Enclosure sizes

Power size [kW (hp)] Voltage

[V]

1 cable [m

(ft)]

2 cables [m (ft)] 3 cables [m

(ft)]

4 cables [m (ft)]

500

150 (492)

75 (246)

50 (164)

37 (121.4)

A3

1.1–7.5 (1.5–10)

525–690

100 (382)

50 (164)

33 (108)

25 (82)

B4

11–30 (15–40)

525–690

150 (492)

75 (246)

50 (164)

37 (121.4)

C3

37–45 (50–60)

525–690

150 (492)

75 (246)

50 (164)

37 (121.4)

10.8.3 Motor Insulation

Modern motors for use with drives have a high degree of insulation to account for new generation high-efficiency IGBTs with high

dU/dt. For retrofit in old motors, confirm the motor insulation or mitigate with dU/dt filter or, if necessary, a sine-wave filter.

For motor cable lengths ≤ the maximum cable length listed in , the motor insulation ratings listed in

are recommended. If a

motor has lower insulation rating, use a dU/dt or sine-wave filter.

Table 86: Motor Insulation Ratings

Nominal mains voltage [V]

Motor insulation [V]

U

N

≤ 420

Standard U

LL

=1300

420 V < U

N

≤ 500

Reinforced U

LL

=1600

500 V < U

N

≤ 600

Reinforced U

LL

=1800

600 V < U

N

≤ 690

Reinforced U

LL

=2000

10.8.4 Motor Bearing Currents

To minimize DE (Drive End) bearing and shaft currents, ground the drive, motor, driven machine, and motor to the driven machine

properly. For more information, refer to the

Minimizing Bearing Failures in AC Drive Systems User Guide

.

Standard mitigation strategies

Use an insulated bearing.

Apply rigorous installation procedures:

Ensure that the motor and load motor are aligned.

Strictly follow the EMC Installation guideline.

Reinforce the PE so the high-frequency impedance is lower in the PE than the input power leads.

Provide a good high-frequency connection between the motor and the drive for instance by shielded cable which has a

360° connection in the motor and the drive.

Make sure that the impedance from the drive to the building ground is lower than the grounding impedance of the ma-

chine. This can be difficult for pumps.

Make a direct ground connection between the motor and load motor.

Lower the IGBT switching frequency.

Modify the inverter waveform, 60° AVM vs. SFAVM.

Install a shaft grounding system or use an isolating coupling.

Apply conductive lubrication.

Use minimum speed settings if possible.

Try to ensure that the line voltage is balanced to ground. This can be difficult for IT, TT, TN-CS, or Grounded leg systems.

10.9 Braking

10.9.1 Selection of Brake Resistor

To handle higher demands by regenerative braking, a brake resistor is necessary. Using a brake resistor ensures that the energy is

absorbed in the brake resistor and not in the drive. For more information, see the VLT® Brake Resistor MCE 101 Design Guide.

AJ300847815559en-000101 / 130R0337

138 | Danfoss A/S © 2020.09

Electrical Installation

Considerations

VLT® AQUA Drive FC 202

Design Guide