10.5 Control Wiring and Terminals

10.5.1 Shielded Control Cables

Usually, the preferred method is to secure control and serial communication cables with shielding clamps provided at both ends to

ensure the best possible high frequency cable contact.

If the ground potential between the drive and the PLC is different, electric noise could disturb the entire system. Solve this problem

by fitting an equalizing cable as close as possible to the control cable. Minimum cable cross-section: 16 mm

2

(6 AWG).

1

2

PE

FC

PE

PLC

e3

0b

b9

22

.1

2

PE

PE

<10 mm

Illustration 64: Shielding Clamps at Both Ends

1

Minimum 16 mm

2

(6 AWG)

2

Equalizing cable

10.5.1.1 50/60 Hz Ground Loops

With long control cables, ground loops may occur. To eliminate ground loops, connect 1 end of the shield to the ground with a

100 nF capacitor (keeping leads short).

100nF

FC

PE

PE

PLC

<10 mm

e3

0b

b6

09

.1

2

Illustration 65: Connection with a 100 nF Capacitor

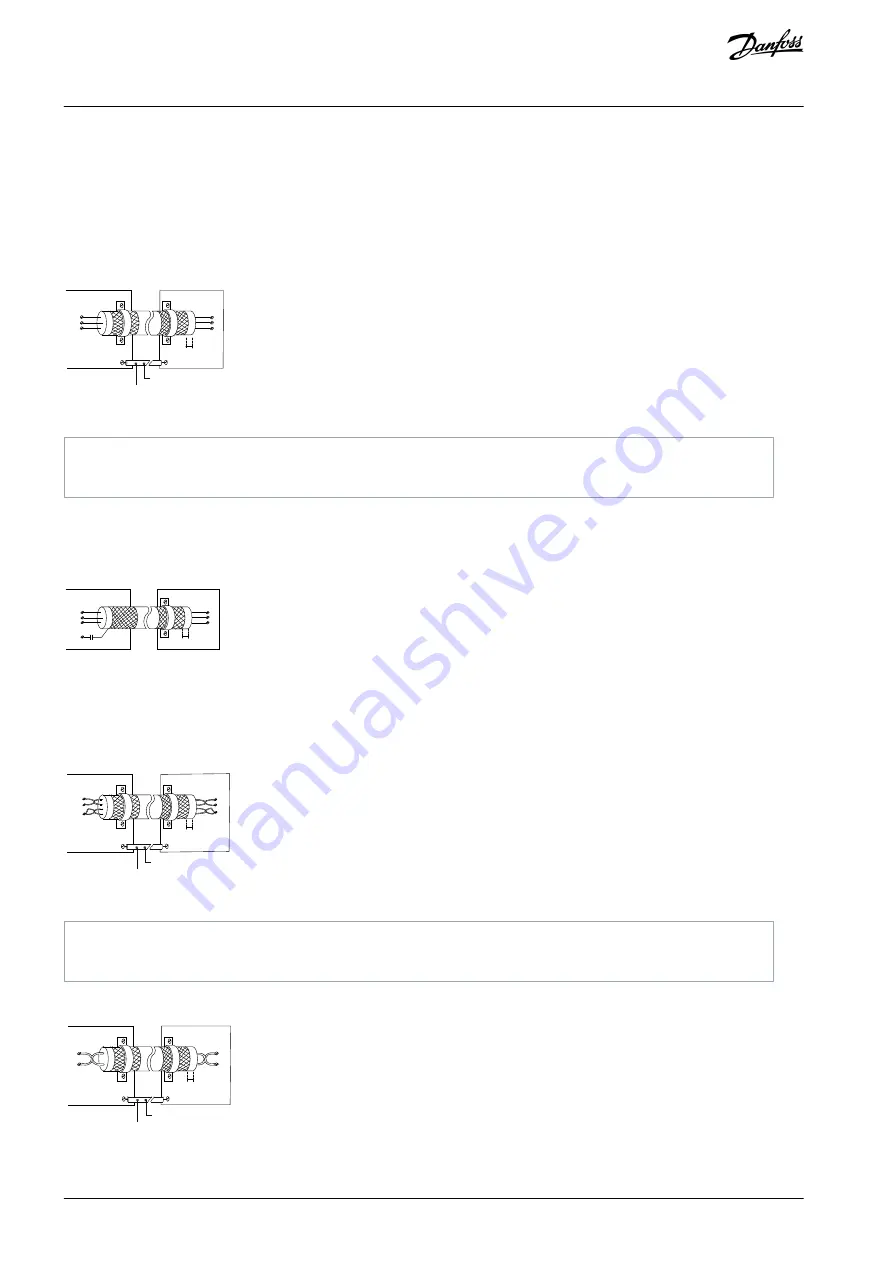

10.5.1.2 Avoid EMC Noise on Serial Communication

This terminal is connected to ground via an internal RC link. Use twisted-pair cables to reduce interference between conductors. The

recommended method is shown in the following illustration.

PE

FC

PE

FC

e3

0b

b9

23

.1

2

PE

PE

69

68

61

69

68

61

1

2

<10 mm

Illustration 66: Twisted-pair Cables

1

Minimum 16 mm

2

(6 AWG)

2

Equalizing cable

Alternatively, the connection to terminal 61 can be omitted.

PE

FC

PE

FC

e

3

0

b

b

9

2

4

.1

2

PE

PE

69

69

68

68

1

2

<10 mm

Illustration 67: Twisted-pair Cables without Terminal 61

AJ300847815559en-000101 / 130R0337

122 | Danfoss A/S © 2020.09

Electrical Installation

Considerations

VLT® AQUA Drive FC 202

Design Guide