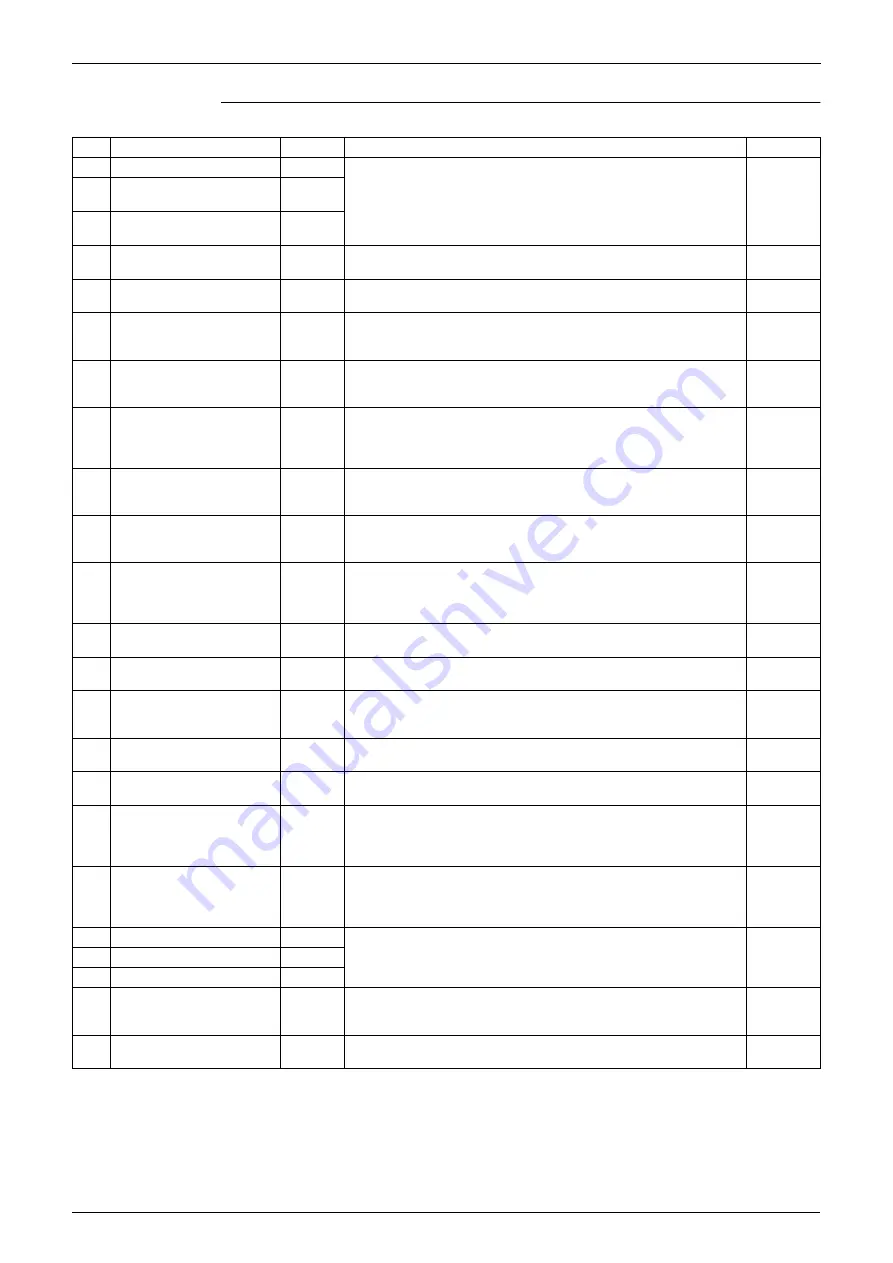

Refrigerant System Diagram

Si33-105

34

Function R407C PLUS Series Heat Recovery System

RSEYP24~30KJY1

No.

Name

Code

Function

Remarks

A

Inverter compressor

M1C

Combination of a compressor (inverter compressor) capable of

operating at 29-95 Hz with inverter drive and compressors

(constant-speed compressors) operable only on commercial

power supply achieves multi step control.

B

Constant-speed

compressor 1

M2C

C

Constant-speed

compressor 2

M3C

D

4 way valve

Y1R

Change the refrigerant flow to the main unit heat exchanger 1 and

2, to switch the condenser

↔

evaporator.

E

4 way valve

Y2R

Change the refrigerant flow to the sub-unit heat exchanger to

switch the condenser

↔

evaporator.

F

4 way valve

Y3R

Change the refrigerant flow to the outdoor main unit discharge line

to switch the high temperature high pressure gas

↔

low

temperature & low pressure gas.

J

Electronic expansion valve

Y1E

(For main unit heat exchangers 1)

Provides PI control during evaporator to maintain constant

superheated degree (SH).

Main unit

’

s

left side

exchanger

K

Electronic expansion valve

Y2E

(For main unit heat exchangers 2)

Provides PI control during evaporator to maintain constant

superheated degree (SH).

Main unit

’

s

right side

heat

exchanger

L

Electronic expansion valve

Y3E

(For sub unit’s heat exchanger)

Provides PI control during heating operation to maintain constant

superheated degree (SH).

MSolenoid valve

Y1S

(For auxiliary condensers)

Use for heat exchanger capacity control during simultaneous

cooling / heating operation.

N

Solenoid valve

Y2S

(For hot gas bypass and pressure equalization)

Bypasses hot gas during transitional operation such as defrosting

operation to prevent sudden decrease of low pressure. Also

equalizes pressure to reduce startup load.

O

Solenoid valve

Y3S

(For inverter unit liquid injection)

Provides liquid injection to prevent overheating operation.

P

Solenoid valve

Y4S

(For receivers)

Use for pump-down refrigerant to receiver.

Q

Solenoid valve

Y5S

(For liquid pressure control)

Use for maintaining liquid pressure during heat exchanger capacity

control.

R

Solenoid valve

Y6S

(For constant-speed comp. 1 liquid injection)

Provides liquid injection to prevent overheating operation.

S

Solenoid valve

Y7S

(For constant-speed comp. 2 liquid injection)

Provides liquid injection to prevent overheating operation.

T

High pressure sensor

SENPH

Heating operation: Provides PI control for compressors and heat

exchanger by detecting high pressure.

Cooling operation: Controls compressors to ensure sufficient high

pressure when outside temperature is low.

U

Low pressure sensor

SENPL

Cooling operation: Provides PI control for compressors and heat

exchanger by detecting low pressure.

Heating operation: Controls motorized valves to maintain constant

evaporator superheated degree.

V

High pressure switch

Q1PH

Opens at set pressure of 2.94 MPa to stop operation.

W

High pressure switch

Q2PH

X

High pressure switch

Q3PH

Y

Pressure regulating valve

Pressure relief valve to protect liquid sealing in receiver piping

during transportation or storing.

It opens at 2.65 MPa.

Z

Fusible plug

Plug head melt at 70~75°C around receiver and high pressure and

high temperature refrigerant is relived.

Summary of Contents for R407C PLUS

Page 1: ...System R407C PLUS Series Heat Recovery System Si33 105 Service Manual ...

Page 11: ...Introduction Si33 105 x ...

Page 41: ...Specifications Si33 105 30 Specifications R407C PLUS Series Heat Recovery System ...

Page 147: ...Test Operation Si33 105 136 Test Operation R407C PLUS Series Heat Recovery System ...

Page 263: ...Si33 105 iv Index ...