S0708315K

Page 34

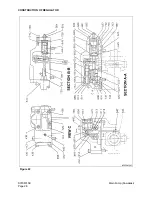

Main Pump (Kawasaki)

2.

Adjustment of flow control characteristic

The flow control characteristic can be

adjusted with the adjusting screw.

Adjust it by loosening the hexagon nut

(801) and by tightening (or loosening) the

hexagonal socket head screw (924).

Tightening the screw shifts the control

chart to the right as shown in the Figure

25.

NOTE:

Adjusting values are shown in

the attached Table. See

“Summary of Regulator

Adjustment Values” on

page -38.

Total Horsepower Control

The regulator decreases the pump tilting angle

(delivery flow) automatically to limit the input

torque within a certain value with a rise in the

delivery pressure P1 of the self pump and the

delivery pressure P2 of the companion pump.

(The input horsepower is constant when the

speed is constant.)

Since the regulator is of the simultaneous total

horsepower type that operates by the sum of

load pressures of the two pumps in the tandem

double-pump system, the prime mover is

automatically prevented from being overloaded,

irrespective of the load condition of the two

pumps, when horsepower control is under way.

1.

Functional explanation

Since this regulator is of the simultaneous total horsepower type, it controls the tilting angles

(displacement volumes) of the two pumps to the same values as represented by the following

equation:

•

T in = P1 x q/2

π

+ P2 x q/2

π

= (P1 + P2) x q/2

π

The horsepower control function is the same as the flow control function and is summarized in the

following. (For detailed behaviors of respective parts, refer to the section of flow control).

A.

Overload Preventive Function

When the self pump delivery pressure P1 or the companion pump delivery pressure P2 rises, it

acts on the stepped part of the compensating piston (621). It presses the compensating rod

(623) to the right till the force of the outer spring (625) and inner spring (626) balances with the

hydraulic force. The movement of the compensating rod is transmitted to Lever 1 via pin (875).

Lever 1 rotates around the pin (875) (E) attached to the casing (601).

Since the large-hole section (F) of Lever 1 contains a protruding pin (897) attached to the

feedback lever (611), the feedback lever rotates around the fulcrum of Point D as Lever 1

rotates, and then the spool (652) is shifted to the right. As the spool moves, the delivery

pressure P1 is admitted to the large-diameter section of the servo piston via Port C liter, causes

Figure 25

Figure 26

Summary of Contents for Solar 300LC-V

Page 2: ......

Page 4: ......

Page 7: ...1SAFETY...

Page 8: ......

Page 46: ...S0102000 Page 38 Track Excavator Safety...

Page 47: ...1SPECIFICATIONS...

Page 48: ......

Page 54: ...S0202080K Page 6 Specifications for Solar 300LC V...

Page 70: ...S0202080K Page 22 Specifications for Solar 300LC V...

Page 71: ...1GENERAL MAINTENANCE...

Page 72: ......

Page 86: ...S0302000 Page 14 General Maintenance Procedures Return to Master Table of Contents...

Page 99: ...1UPPER STRUCTURE...

Page 100: ......

Page 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6...

Page 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents...

Page 140: ...S0407000 Page 6 Swing Bearing...

Page 164: ...S0408070K Page 24 Swing Reduction Gear...

Page 165: ...1LOWER STRUCTURE AND CHASSIS...

Page 166: ......

Page 190: ...S0505000 Page 24 Track Assembly 7 Tighten plug 1 Figure 48 Figure 48...

Page 191: ...S0505000 Page 25 Track Assembly TRACK SPRING AND TRACK ADJUSTING CYLINDER PARTS LIST Figure 49...

Page 193: ...1ENGINE AND DRIVE TRAIN...

Page 194: ......

Page 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12...

Page 220: ...S0605060K Page 26 Air Conditioner...

Page 229: ...1HYDRAULICS...

Page 230: ......

Page 262: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4...

Page 266: ...S0703010K Page 6 Accumulator...

Page 274: ...S0704080K Page 8 Center Joint Swivel...

Page 283: ...S0705000 Page 9 Cylinders...

Page 287: ...S0705000 Page 13 Cylinders...

Page 291: ...S0705000 Page 17 Cylinders...

Page 299: ...S0705000 Page 25 Cylinders...

Page 308: ...S0705000 Page 34 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28...

Page 312: ...S0705000 Page 38 Cylinders...

Page 324: ...S0707270K Page 12 Swing Motor Toshiba MFC200 PARTS LIST Figure 6...

Page 355: ...S0707315K Page 11 Travel Motor with Gearbox...

Page 424: ...S0708315K Page 28 Main Pump Kawasaki CONSTRUCTION OF REGULATOR Figure 22...

Page 444: ...S0708315K Page 48 Main Pump Kawasaki...

Page 450: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1...

Page 451: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2...

Page 453: ...S0709401K Page 9 Main Control Valve Kayaba...

Page 455: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4...

Page 467: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16...

Page 500: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54...

Page 552: ...S0792160K Page 6 Hydraulic Schematic S300LC V...

Page 553: ...1ELECTRICAL SYSTEM...

Page 554: ......

Page 608: ...S0802220K Page 54 Electrical System...

Page 627: ...S0802220K Page 73 Electrical System...

Page 634: ...S0892160K Page 4 Electrical Schematic S300LC V SOLAR 300LC V Figure 2...

Page 636: ...S0892160K Page 6 Electrical Schematic S300LC V...

Page 637: ...1ATTACHMENTS...

Page 638: ......

Page 658: ......