MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 16

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

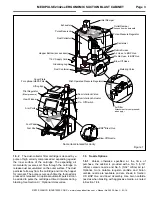

5.8.8

To find the static pressure, add the number of

inches the fluid travels up one column to the inches the

fluid travels down the other column. Refer to the

example in Figure 21.

5.8.9

After taking the readings, replace the needle

protector. Close the manometer valves and store the

manometer in the original container in a clean area.

Note: If the manometer installation is permanent, the

manometer may remain on the reclaimer body after the

valves are closed.

5.9

Foot Shelf

5.9.1

Raise the shelf to remove pressure from the

locating pins and remove the pins. Adjust the shelf

height and insert the pins.

6.0

PREVENTIVE MAINTENANCE

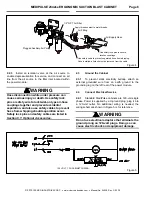

WARNING

Failure to wear an approved respirator and

personal protection when servicing dust-laden

areas of the cabinet and dust collector, as well as

when emptying the container, could result in lung

disease, serious skin or eye irritation, or other

health issues. Toxicity and health risk vary with

type of media and dust generated by blasting.

The respirator must be approved for the type of

dust generated. Identify all material being

removed by blasting and obtain a safety data

sheet (SDS) for the blast media.

To avoid unscheduled downtime and to improve safety,

establish an inspection schedule. Inspect all parts

subjected to media contact, including the gun and

nozzle, media hose, flex hose, wear plate, and all items

covered in this section. Adjust frequency of inspections

as needed, based on the following:

Usage:

Frequently used cabinets require more

maintenance

and

inspections

than

those

occasionally used.

Type of media:

Aggressive media wears parts

faster than nonaggressive media.

Condition of parts being blasted:

Heavily

contaminated parts require more maintenance to

the cabinet’s media recovery system.

Friability of media:

Media that rapidly breaks

down require more maintenance to the cabinet’s

media recovery system and dust collector.

6.1

Daily Inspection and Maintenance Before

Blasting with the Air OFF

6.1.1 Check media level:

Check media level in

reclaimer and refill as necessary.

6.1.2 Inspect reclaimer debris screen and door

gasket:

Check reclaimer debris screen for debris. The

screen is accessible through the reclaimer door. With

the exhauster OFF, remove the screen and empty it

daily or when loading media. Empty the screen more

often if part blasted causes excessive debris. Do not

operate the machine without the screen in place;

oversized byproduct from blasting could plug the nozzle.

While the door is open, inspect the door gasket for wear

or damage. Replace the gasket at the first sign of wear.

6.1.3 Drain compressed-air filter:

The cabinet is

equipped with a manual-drain air filter. Drain the filter at

least once a day, and more often if water is present.

Moist air inhibits the flow of media. Drain the air line and

receiver tank regularly. If the filter does not remove

enough moisture to keep media dry and flowing, it may

be necessary to install an air dryer or aftercooler in the

compressed-air supply line.

6.1.4

Inspect dust container:

Empty the dust

container regularly. Start by inspecting the container at

least daily and when adding new media, then adjust

frequency based on usage, contamination, and friability

of the media.

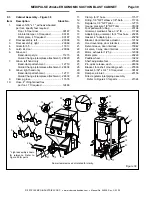

1.

Turn off the exhauster and

unlatch the lid lock ring from

the dust container, as shown in Figure 22.

2.

Pry off the lid from the container (the lid's flexible inlet

hose allows easy removal) and remove the container.

Figure 22

3.

Tie off or otherwise seal the top of the liner and

remove it from the container. Dispose of the sealed liner

into a suitable disposal receptacle.

Drum Liner

Latch Catch

Swing the catch

up to unlock the

lock-ring latch.

Latch

Pull the latch away

from the ring and

remove the ring.