MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 21

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

7.8

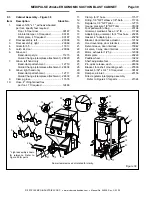

Replacing Reclaimer Wear Plate ‒ Figure 28

WARNING

To access wear-plate mounting screws, the

reclaimer must be removed from the power

module. MediPulse reclaimers weigh about 100

lbs. When removing and installing the

reclaimer, it must be adequately supported and

secured to appropriate lift equipment. Failure to

secure and use proper lift device can result in

injury.

7.8.1

Remove the flex hose from the reclaimer inlet.

7.8.2

Remove the media hose from the metering valve.

7.8.3

Remove the reclaimer mounting bolts and

remove the reclaimer from the power module.

7.8.4

Remove the reclaimer inlet-pipe adaptor,

adaptor gasket, and old wear plate. The wear plate is

held in place by screws attached from the outside of the

reclaimer. Remove the screws and pull out the wear

plate through the reclaimer inlet.

Figure 28

7.8.5

Remove remnants of old caulk that will prevent

the new wear plate from seating against the reclaimer

wall and top.

7.8.6

Angle the new wear plate into the reclaimer inlet

and position it so the straight end is flush with the inlet.

Use locking pliers, clamps or other means to hold the

wear plate in position, making sure the leading edge of

the wear plate is aligned with the reclaimer inlet and that

the top edge is even with the top of the reclaimer.

7.8.7

Install the front two sheet-metal screws through

the old screw holes to secure.

7.8.8

Use a board or similar object as leverage to pry

the wear plate against the inner wall of the reclaimer.

7.8.9

New self-drilling sheet-metal screws are

provided with the wear plate; while forcing the wear plate

against the reclaimer wall, install the screws through the

remaining screw holes to secure. Rearrange the pry

board as needed to press the wear plate against the

reclaimer wall when installing screws.

7.8.10

To avoid rapid wear, apply RTV caulk to fill gaps

at the seams on the top and bottom of the wear plate

7.8.11

Reattach the inlet-pipe adaptor, replacing the

gasket if it is worn, compressed, or otherwise damaged.

7.8.12

Reinstall the reclaimer.

7.8.13

Connect the flex hose and media hose.

7.8.14

Allow time for the caulking to cure before putting

the reclaimer into service.

7.9

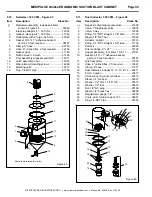

Replacing Filter Cartridge – Figures 29 and 30

WARNING

NO DUST IS SAFE TO BREATHE.

The inhalation of airborne dust can lead to

serious respiratory illness and death, serious

skin or eye irritation, or other health issues.

Always wear approved respiratory protection

when servicing the dust collector, while

handling filter bags and cartridges, and when

emptying the dust container. Toxicity and

health risk vary with type of media and dust

generated by blasting. The respirator must be

approved for the type of dust generated.

Identify all material being removed by blasting

and obtain a safety data sheet (SDS) for the

blast media.

7.9.1

Close the air-supply valve and open the drain to

bleed air from the pulse reservoir.

7.9.2

Refer to Figure 29 and unlatch the dust

container lid, pry off the lid from the container (the lid's

flexible inlet hose allows easy removal), and remove the

container.

Align leading edge and

clamp where needed.

Use board to pry back of wear plate against

reclaimer wall and then install screws.

Screws

Wear Plate