MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 17

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

NOTE: Blasting media is usually nontoxic; however,

some materials being removed by the blast process

may be toxic. Obtain SDS sheets for the media and

identify all material removed by the blast process.

Check with proper authorities for disposal

restrictions.

4.

Place a new liner inside the container and drape it

over the top edge. Reattach the container to the lid and

latch the lock ring, making sure the lid and clamp are

secure. Replacement liners are shown in Sections 9.11.

6.2

Daily Inspection During Blasting – Have

Someone Do the Following:

6.2.1 Inspect cabinet for dust leaks:

During

operation, inspect cabinet door seals for media leaks.

Dust leaking from the inlet damper or other places on

the cabinet indicates saturated filter cartridge. Refer to

Section 6.2.4 for additional pulsing.

6.2.2 Check exhaust air for dust:

Dust discharge at

the outlet indicates a leaking or damaged filter cartridge.

Check immediately. Note that a small amount of dust

egress is normal for a short time before a new cartridge is

seasoned.

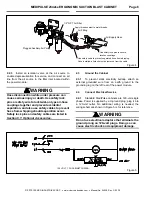

6.2.3 Drain pulse reservoir ‒ Figure 23:

Open the

petcock to drain water from the pulse reservoir before

and after each use.

Figure 23

6.2.4 Additional cartridge pulsing:

The cartridge is

pulsed each time the foot pedal is pressed or released.

Additional pulsing should be performed per the following

instructions every eight hours, or more often under dusty

conditions, to prevent clogging of the cartridge.

1.

Turn OFF exhauster.

2.

Hold the blast gun and rapidly press and release the

foot pedal three times. Activating the foot pedal more

than three times may cause dust to escape from the

enclosure.

3.

Start the exhauster and let it run for 10 seconds or

until all airborne dust is cleared from the cabinet.

4.

Repeat the process several times.

6.3

Weekly Inspection and Maintenance Before

Blasting with Air OFF

6.3.1 Inspect view-window cover lens:

Inspect the

window cover lens. Replace as needed, per Section 7.3.

6.3.2 Inspect gloves:

Inspect gloves for wear. The

first sign of deterioration may be excessive static

shocks. Replace as needed, per Section 7.1.

6.3.3 Inspect BNP

®

gun assembly:

Inspect internal

parts of the BNP gun for wear. Inspection and

replacement of the air jet cover before it wears through

will prolong the life of the jet. Replace parts as needed,

per Section 7.2.

6.3.4 Inspect media hose:

Inspect media hose for

thin spots by pinching it every 6 to 12 inches. Replace

the hose when it becomes soft.

6.4

Weekly Inspection During Blasting – Have

Someone do the Following:

6.4.1 Inspect flex hoses:

Inspect flex hoses for leaks

and wear.

Drain

Pulse Reservoir