MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 11

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

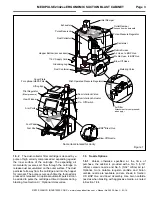

4.4.3

Close door; the door interlock system will

prevent blasting if either door is open.

4.5

Blasting Operation

WARNING

To avoid the inhalation of dust, which can

cause respiratory illness from short-term

ingestion or death from long-term ingestion:

Use the blow-off nozzle to blow media off

parts before opening doors.

After blasting, keep doors closed and

exhauster running until the cabinet is clear

of all airborne dust.

Always close cabinet, reclaimer, and dust

collector doors before blasting. Keep all

doors closed during blasting.

Always wear blast gloves.

Stop blasting immediately if dust leaks are

detected.

4.5.1

Slowly open the air valve on the air-supply hose

to the cabinet. Check for air leaks on the initial start up

and periodically thereafter.

4.5.2

After the filter cartridge is seasoned, per Section

7.10, adjust the pulse pressure regulator to 60 psi. Refer

to Section 5.6 for adjustment procedure.

4.5.3

Turn ON lights and exhauster. The ON/OFF

toggle switch performs both functions.

4.5.4

Load parts.

4.5.5

Close door; the door interlock system will

prevent blasting if either door is open.

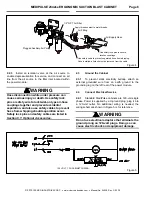

4.5.6

Adjust the pilot pressure regulator to the

required blast pressure, per Section 5.1. The regulator is

located on the top-left side of the cabinet.

4.5.7

Insert hands into rubber gloves.

4.5.8

To blast, hold the gun firmly, point the gun

toward the object to be blasted, and apply pressure to

the top of the foot pedal; blasting will begin almost

immediately.

WARNING

Shut down the cabinet immediately if dust

discharges from the dust collector or cabinet.

Check to make sure the dust-collector filter

cartridge is correctly seated and that it is not

worn or otherwise damaged. Prolonged

breathing of any dust can result in serious lung

disease. Short-term ingestion of toxic dust,

such as lead or heavy metals, poses an

immediate danger to health. Toxicity and health

risks vary with type of media and dust

generated by blasting. Identify all material being

removed by blasting and obtain a safety data

sheet (SDS) for the blast media.

4.5.9

When blasting small parts, place an appropriately

sized screen over the grate to prevent parts from falling

into the hopper. If an object should fall through the grate,

stop blasting immediately and retrieve it.

NOTICE

To prevent rapid frosting of the view window,

install a view-window cover lens, per Section

7.3, and avoid pointing the blast nozzle toward

the view window

4.5.10

When blasting parts off the grate, use a solid

conductive backrest to support the part. Without this

assist, especially with longer blasting operations, the

operator will tire easily from resisting blast pressure, and

static electricity could build up in the ungrounded part

and cause static shocks. Whenever possible, avoid

holding small parts that require blasting into the glove.

4.6

Blasting Technique

4.6.1

Blasting technique is similar to spray painting

technique. Smooth, continuous strokes are usually most

effective. The distance from the part affects size of blast

pattern. Under normal conditions, hold the gun

approximately 3" to 6" from the surface of the part.

4.7

Stop Blasting

4.7.1

To stop blasting, remove foot pressure from the

top of the foot pedal.

4.7.2

Use the blow-off nozzle to blow media off

cleaned parts.