MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 26

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

8.17

Dust collector does not pulse when foot

pedal is pressed or released

8.17.1

Check pressure on dust-collector pulse-pressure

gauge. If low, adjust pulse pressure, per Section 5.6.

8.17.2

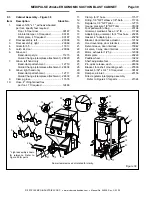

Refer to Figure 31 and make sure the 3-way

pulse valve has not come loose from the mounting

bracket. Tighten the retaining nut as needed to secure.

8.17.3

If the cam follower tilts to one side, one or both

roll pins are bent or missing. Remove the two screws on

the bottom of the pedal and remove the switch and cam

follower assembly. Center the cam follower and replace

roll pins as needed to hold the cam follower in place.

Refer to Figure 31.

Figure 31

8.17.4

Check alignment of pulse-valve cam follower:

With the exhauster running and with blast pressure

adjusted to 0 psi, hold the foot pedal in hand and fully

press the pedal top. The collector should pulse as the

cam follower rides over the lobe on the pedal top when

the pedal is pressed, and again when the pedal is

released, as shown in Figure 31. Note: The pedal should

be rapidly pressed and released so the cam follower

quickly rides over the lobe; prolonged engagement of

the pulse valve will lengthen the pulse, which does not

clean the cartridge and wastes compressed air.

The lobe on the pedal top should press the cam follower

IN to engage the 3-way pulse valve, and disengage the

switch when the pedal is fully pressed and again when

the pedal is released. If the switch is not aligned to

function as described, align as follows:

If the switch does not disengage the pulse when the

cam follower rides off the lobe, the switch assembly

is too close to the lobe. Loosen the two screws on

the bottom of the pedal, slide the switch away from

the lobe as needed, and recheck alignment.

If the switch does not engage the pulse when the

cam follower rides onto the lobe, the switch

assembly is too far from the lobe. Loosen the two

screws on the bottom of the pedal, slide the switch

toward the lobe as needed, and recheck alignment.

When the alignment is set correctly, tighten the screws

to prevent movement.

When the pedal is operating correctly, a spurt of air should

be heard as the cam follower rides off the lobe when the

pedal is pressed and again when it is released. If the

cam follower is working correctly, and there is no spurt

of air when the pedal is pressed and released, it is likely

a problem with the 3-way valve; replace the 3-way valve.

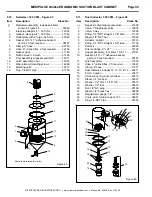

8.17.5

Check the diaphragm pulse valve and actuator

assembly. Refer to Figure 32.

8.17.5.1

Remove the pilot actuator from the 3-way

pulse valve. With the exhauster running and with blast

pressure adjusted to 0 psi, press in on the 3-way valve

plunger; the cartridge should pulse when the plunger is

pressed and stop when released.

If the cartridge does pulse, the diaphragm pulse

valve and 3-way valve are functioning; proceed to

Section 8.17.5.2.

If it does not pulse, listen for a spurt of air coming

from the 3-way exhaust port when the plunger is

pressed.

If it does spurt air, the problem is likely in the

diaphragm pulse valve. Inspect the diaphragm for

wear or damage.

If it does not spurt air, the 3-way valve is not

functioning. Replace the 3-way valve.

Lobe

Cam Follower

Pulse Valve Plunger

Foot Pedal Top

Cam follower rests off

the bottom of the lobe

(no pulse).

Cam follower rests off

the top of the lobe

(no pulse).

3-Way

Pulse Valve

Pedal Base

The lobe pushes cam

follower in, pushing

pulse switch plunger in,

and pulses cartridge.

Roll Pins

Keeps follower upright.

Loosen screws and slide bracket as necessary to

pulse when the follower is on the lobe, and not pulse

when follower is off the lobe (when the pedal is fully

pressed or fully released).

Foot pedal top up - nonblast position.

Pedal top partially pressed down.

Foot pedal top fully pressed down.

Mounting Bracket

Bracket Screws