MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 12

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

4.7.3

Keep doors closed and exhauster running until

the cabinet is clear of all airborne dust.

4.7.4

Unload parts.

4.8

Pulsing (cleaning) Dust Collector Cartridge

4.8.1

The dust-collector filter cartridge is pulsed each

time the foot pedal is pressed or released. Prolonged

periods of blasting or dusty conditions may require the

cartridge to be pulsed during the blasting process, per

Section 6.2.4, or upgrade to an automatic pulse kit. See

Section 9.1.

4.9

Shutdown

4.9.1

Shut off the air-supply valve, bleed the air-

supply line, and drain the compressed-air filter and dust-

collector pulse reservoir.

4.9.2

Switch OFF the lights and exhauster.

5.0

ADJUSTMENTS

5.1

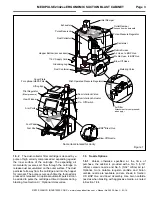

Blasting Pressure (pilot regulator) – Figure 14

5.1.1

The pilot regulator (located on the top-left side of

the cabinet), enables the user to adjust blasting pressure

while blasting, to suit the application. The suitable

pressure for most purposes is about 80 psi. Lower

pressures may be required on delicate substrates and will

reduce media breakdown. Higher pressure may be

required for difficult blasting jobs on durable substrates,

but it could increase media break down. If pressure is too

high, suction in media hose will decrease, and if high

enough can cause blow-back in the media hose. Optimal

production can only be achieved when pressure is

carefully monitored.

Figure 14

5.1.2

To adjust pressure, unlock the knob by pulling it

out, as shown in Figure 14, and turn it clockwise to

increase pressure or counterclockwise to decrease

pressure. Pressure may drop slightly from closed-line

pressure when blasting starts. Once operating pressure

is set, push the knob to lock it and maintain the setting.

5.2

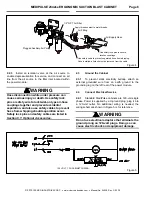

Air Jet Adjustment ‒ Figure 15

5.2.1

Thread the air jet 4-1/2 to 5 full turns into the gun

body. Doing so leaves 3-1/2 to 4 threads exposed past the

lock nut. Tighten the lock nut to maintain the setting. Refer

to Section 9.2 for optional adjusting tool, which correctly

positions the jet. Instructions are provided with the tool.

Figure 15

5.3

Media-Air Mixture, Figure 16

5.3.1

Check the media stream for correct media-air

mixture; media flow should be smooth and appear as a

light mist coming from the nozzle.

Figure 16

5.3.2

If media does not flow smoothly, loosen the

locking nut, and adjust the metering screw until the

upper holes in the metering stem are closed off and the

lower holes are fully open, as shown in Figure 16. This

adjustment is a starting point.

5.3.3

If pulsation occurs in the media hose, either

media is damp and caked, or not enough air is

entering the media stream. While blasting, loosen the

lock nut and slowly turn the adjusting screw out

Adjusting Screw

Locking Nut

Lower holes fully open.

Upper holes

fully closed.

When viewed from the knob end,

turn clockwise to increase pressure;

turn counterclockwise to decrease pressure.

Adjustment Knob

Lock Nut

Air Jet Hex

Blast Pressure Regulator

Located on top-left

side of cabinet.

Push knob in to lock.

Pull knob out to unlock

and adjust pressure.

3-1/2 to 4 threads between

lock nut and air jet hex.