MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 15

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

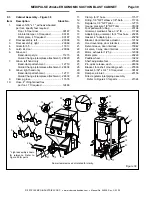

5.8.1

Refer to instructions packed with the manometer

for preparing and operating the manometer.

5.8.2

Connect one end of the 3/16" ID tubing to one of

the tubing connectors (elbow) at the top of the

manometer by pushing it over the barbed adaptor.

5.8.3

Open both manometer valves (elbows), per the

instructions with the manometer.

5.8.4

Magnets on the manometer hold it in position on

the reclaimer body or dust-collector body. The

manometer must be vertical so the fluid is level on both

sides.

5.8.5

Adjust the slide rule to align the zero with the

fluid level. Refer to Figure 21.

5.8.6

Needle placement:

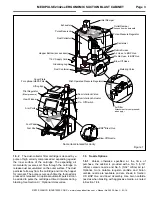

Figure 20 shows the

manometer setup for taking both periodic and frequent

static-pressure readings.

Figure 20

5.8.6.1

Taking frequent readings using a permanent

fitting:

A permanent fitting may be installed in the

reclaimer wall, as shown in Figure 20, for taking frequent

static-pressure readings. Permanent fittings must have a

barb to accommodate the 3/16" ID tubing and have a

means of sealing the fitting when the manometer is not

in use. Use silicone sealer or other sealant to seal

around the fitting to prevent leaks. The fitting should be

capable of being capped when the manometer tube is

removed. Sealing the fitting will prevent leaks that alter

the reclaimer’s separation efficiency. Air drawn into the

reclaimer will cause carry over of good media to the dust

collector.

5.8.6.2

To take occasional readings:

Leave the

needle protector on the needle and insert the needle into

the unused end of the tubing. The ends of the tubing

must fit tight on the manometer and needle; leaks will

give inaccurate readings. Open the reclaimer fill door,

remove the needle protector, and place the needle so

the point is inside the door opening. Carefully close the

door on the needle. The side of the needle will embed

into the rubber door gasket, creating an airtight seal

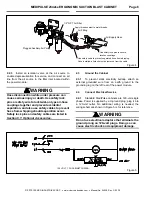

5.8.7

Open cabinet doors and turn the exhauster ON.

The negative (static) pressure will move fluid in the tube.

NOTE: Readings must be taken with the cabinet

doors open and with the exhauster running.

Figure 21

The manometer must be vertical

when taking pressure readings.

With the exhauster OFF,

slide the rule to align the

zero with the fluid level.

To obtain the pressure reading: With the

exhauster ON, add the number of

inches the fluid travels up the column to

the inches the fluid travels down the

other column. The total is the static-

pressure reading.

In the example shown, fluid traveled up

the right column 1-3/4"

and down the left column 1-3/4".

Static pressure is determined by adding

the columns together. In the example,

the static pressure is 3-1/2 ".

Refer to Paragraph 5.8.6.2.

When taking occasional

readings, position the

needle so the point is inside

the door opening. Carefully

close the door on the

needle.

Refer to Paragraph 5.8.6.1.

For taking frequent readings,

remove plug and install a

permanent fitting in the

coupling, as shown.

Reclaimers are for reference and

may differ from those shown.

Reclaimer Fill Door