P1788E 06/04

9

140/160PTH.C..

5. What to Do If...

...the torque is too low?

-

Is the throttle exhaust adjusted correctly?

-

Is the flow pressure too low?

-

Is the reverse button not in one of its end positions?

-

Is the inlet screen dirty?

-

Is the muffler dirty?

-

Is sufficient oil in the pulse unit?

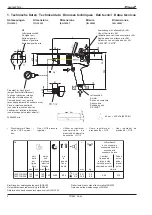

6. Repair Instructions

6.1 Motor Disassembly

-

Clamp the tool in a vice with plastic jaws on its pistol grip <1>.

Caution!

Caution!

Do not damage the rubber coating of the grip.

-

Loosen housing <88>/<133> by turning counterclockwise using a

strap wrench.

-

Pull off housing together with pulse unit.

-

Remove countersunk screw <11> and reverse button <10>.

-

Knock pistol grip housing on soft surface and take motor parts out.

6.2 Trigger Valve Disassembly

-

Lift the plastic trigger button <20> out with 2 screwdrivers

-

Loosen the plug <19> with pin wrench

<F>

(pitch 11 mm, diameter

2 mm) counterclockwise.

-

Pull the loosened valve unit vertically down and out

6.3 Motor Assembly

Caution!

Caution!

To avoid damage to the o-rings apply grease (part n°

914392) to them before mounting.

Be sure to assemble the parts in the sequence shown on

the spare parts drawing.

-

Press rotor cover <36> with ball bearing <35> on rotor <41> with

fixture

<D>

(8. Assembly Instructions, fig. 8 + 9)

-

Mount air distributor <34>

-

Mount seal ring <29> in shut-off piston <28>.

-

Slide shut-off ram <32> into rotor (assembly device) and put both

completely into device

<G>

(fig. 11)

-

Install actuating bolt <31> and balls <39>

-

Fit compression spring <30> in drilling

-

Fasten pre-assembled shut-off piston <28> to rotor

-

Lift rotor completely (without shut-off ram <32>) from assembly

device. The shut-off piston is interlocked with the rotor

-

Assemble centrifugal force controller <27> - <21> (7. Spare Parts

Exploded View)

-

Put o-ring <33> into pistol grip

-

Insert the pre-assembled parts in the pistol housing. To do so the

slot at the periphery of the air distributor <34> must be adjusted

concentric to the reverse button groove to enable a setting with the

pin

-

Assemble reverse button <10> and countersunk screw <11>.

-

Insert rotor cylinder <38> with shear keys <37> into pistol grip

housing.

-

Insert the blades <40> into the rotor grooves of <41>.

-

Put the ball bearing <43> and the circlip <44> into the rotor cover

<42> and mount all into the pistol grip housing.

Caution!

Caution!

The drill holes in the rotor cover must remain uncovered

-

Assemble sleeve <45>

-

Slide shut-off ram <32> back into the rotor

Do only switch on motor when pulse unit <50>/<95> and

housing <88>/<133> are assembled

Caution!

Caution!

When installing the screen <6>, be sure the circlip <7> is

lying flat on the screen.

6.4 Pulse Unit Disassembly

Allowed only if filling with oil filling unit

<A>

can be

guaranteed. The pulse unit must have cooled down to

room temperature.

Caution!

Caution!

Be sure retaining rings are not extended excessively

-

Quick-change model: remove first parts <139> - <135>

-

Remove retaining ring <89>/<134> and pull housing <88>/<133>

off pulse unit.

-

Clamp the hydraulic cylinder <58>/<103> slightly in a vice with flat

chops (8. Assembly Instructions, fig. 1).

To avoid endangering health or environment, always

comply with the local regulations for security and prevention

of accidents.

Avoid direct skin contact when working with oil to prevent

skin irritations.

-

Remove set bolt <76>/<121>. Remove ball <75>/<120> by turning

the drive shaft <69>/<114>, keeping the opening away from the

body.

-

Loosen the bearing ring <73>/<118> with the device

<C2>

.

-

Remove the bearing ring above an oil pan and pull the hydraulic

rotor <69>/<114> from the housing.

Hydraulic roller is spring-loaded!

-

By removing the needle roller <84>/<129> all parts built in the

hydraulic rotor can be removed.

-

Clean all parts.

Caution!

Caution!

Always only use original spares from CLECO. Use of

foreign spares entitles the manufacturer of the tool to void

the warranty.

6.5 Assembly of the Pulse Unit

Caution!

Caution!

To avoid damage to the o-rings apply grease (part

n° 914392) to them before mounting.

-

Reassemble by reversing the disassemby process as shown

(7. Spare parts exploded view).

-

Push parts <57> - <52> ( 3/4") or <102> to <97> ( 7/16" ) onto

the hydraulic cylinder <58>/<103> and secure them with the circlip

<51>/<96>

-

Assemble o-ring <63>/<108>, support ring <62>/<107>, o-ring

<71>/<116> and support ring <72>/<117> on hydraulic rotor <69>/

<114>.

-

Fit O-ring <61>/<106>, needle roll <60>/<105> and sleeve <92>/

<141> in the hydraulic rotor

-

Push fixture

<E>

over long side of shaft on hydraulic rotor

(8. Assembly instructions, fig. 2).

-

Insert compression springs and blades over the slots of fixture

<E>

by pressing them down and turning the hydraulic rotor into the

hydraulic rotor slots (fig. 3).

-

Adjust control blade <68>/<113> (with long shaft end) towards

bore in fixture (fig. 4).

-

Assemble needle roller <59>/<104> into hydraulic cylinder.

Summary of Contents for 140PTHC Series

Page 31: ......