8

P1788E 06/04

140/160PTH.C..

<..>/<..>

=

see 7. Spare Parts Ordering List

<..>

Spare parts index for the 3/4" version

/ <..>

Spare parts index for the 7/16" version

2. Product Description

The pulse nutsetter features

-

torque shut-off,

-

alternative air inlet on top. If the top air inlet is used the screwed

plug <46> must be screwed and sealed in the air inlet on the pistol

grip

-

trigger-start with soft-start valve,

-

has a lockable torque adjustment accessible from the outside

-

reversible, RH and LH operation,

-

generates less than 77 dB(A) when idling and at clockwise rotation

-

generates less than 2,5 m/s² vibration when pulsing

-

Optional shut-off signal for connection to electronic verifier

For safety reasons, the tool must always be disconnected

from the air supply during connection and adjustment work

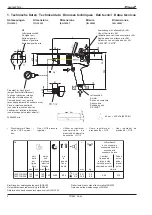

3. Torque Adjustment

-

Square drive model: prevent turning of hydraulic rotor <69> by

using a wrench size 13 (1/2").

-

In quick-change chuck types pull sleeve <136> forward and click

into place to avoid distortion of the hydraulic rotor <114>.

-

Turn valve screw <83>/<128> with a screwdriver size 3

counterclockwise gently until stop is reached (minimum torque

setting).

-

With about 1 - 4 turns clockwise, set the desired torque

(100 - 160 Nm).

-

If pulse rate < 4 free speed reduce speed by turning exhaust air

throttle <3>. Set bolt <8> must be loosened with wrench size 2 first.

-

Turn exhaust air throttle in direction “-”, speed will be reduced.

Caution!

Caution!

Do not reduce the speed below 1800 ¹/min, as the idling

speed can then become unsteady.

4. Inspection and Maintenance

Regular inspection is essential in order to prevent breakdowns, high

repair costs and long downtimes associated with the pulse nutsetter

Always follow and use the safety notes P1687S and this type-specific

operating manual for maintenance and inspection tasks

The inspection and maintenance list below contains timings, checks

and maintenance tasks to be carried out when the pulse nutsetter has

completed 100, 250 and 500 hours of operation

Operating time = number of rundowns x tightening time

Example: Predicative tasks (250 hours of operation) are to be

carried out at an effective tightening time of, for instance, 1.8

seconds after 500000 rundowns

Preventative tasks after 100 hours of operation

-

Inspect suspension for operational reliability

-

Inspect drive for wear

-

Inspect air supply for firm connection

-

Inspect free speed

Predictive tasks after 250 hours of operation

Replacement of (refer to operating manual)

-

Oil change

-

Hydraulic service kit

-

Motor service kit

General overhaul after 500 hours of operation

Inspection of component parts and replacement as necessary of

-

Suspension

-

Trigger valve

-

Exhaust air throttle

-

Motor unit

-

Pulse unit

Our service team will be glad to provide you with additional advice

Turns of valve screw <83> / <128>

Torque (Nm)

Set bolt <8>

(key size 2; Order-No. 920001)

Torque setting

by means of valve screw <83>/<128>

(key size 3; Order-No. 913947)

Speed setting at clockwise rotation

by means of exhaust ait throttle <3>:

If pulse rate < 4 reduce free speed

Free speed not lower than 1800 r.p.m.

Sample adjustment:

•

Bolt M14 8.8 = 135 Nm

•

Torque adjustment about 3 - 4 turns of valve screw

160PTH256

140PTH25Q

Summary of Contents for 140PTHC Series

Page 31: ......