WHEELS

INDEX

page

page

DESCRIPTION AND OPERATION

WHEEL INFORMATION . . . . . . . . . . . . . . . . . . . . 9

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT . . . . . . . . . . . . . . . 10

WHEEL INSPECTION . . . . . . . . . . . . . . . . . . . . . . 9

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE . . . . . . . . . . . . . . . 11

WHEEL INSTALLATION . . . . . . . . . . . . . . . . . . . 11

SPECIFICATIONS

WHEEL SPECIFICATIONS . . . . . . . . . . . . . . . . . 12

DESCRIPTION AND OPERATION

WHEEL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

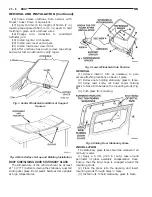

All models use steel or aluminum drop center

wheels. Every wheel has raised sections between the

rim flanges and rim drop well called safety humps

(Fig. 1).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

sections hold the tire in position on the wheel until

the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for the spe-

cific wheel applications used on a vehicle and must

be replaced with equivalent parts.

Do not use replacement parts of lesser quality or of

a substitute design from the original equipment part.

All aluminum wheels have wheel stud nuts with

an enlarged nose. This enlarged nose is necessary to

ensure proper retention of the wheels.

Vehicles that are equipped with bolt-on wheel cov-

ers use large nose wheel nuts. The wheel nuts used

on a vehicle equipped with bolt-on wheel covers are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

Before installing a wheel, remove any buildup of

corrosion on the wheel mounting surface.

WARNING: INSTALLING WHEELS WITHOUT GOOD

METAL-TO-METAL CONTACT COULD CAUSE LOOS-

ENING

OF

WHEEL

LUG

NUTS.

THIS

COULD

ADVERSELY AFFECT THE SAFETY AND HANDLING

OF YOUR VEHICLE.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Wheels must be replaced if they:

•

Have excessive run out

•

Are bent or dented

•

Leak air

•

Have damaged wheel lug holes

Wheel

repairs

employing

hammering,

heating,

welding or repairing leaks are not allowed.

Original equipment replacement wheels are avail-

able through the dealer. When obtaining replacement

wheels from any other source, they must be equiva-

lent in load carrying capacity. The wheel features

(diameter, width, offset, brake clearance, and mount-

ing configuration) must match the original equip-

ment wheels.

WARNING:

FAILURE TO USE ORIGINAL EQUIP-

MENT REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF YOUR

VEHICLE.

Fig. 1 Safety Rim

NS

TIRES AND WHEELS

22 - 9

Summary of Contents for 1998 Voyager

Page 8: ...FASTENER IDENTIFICATION NS INTRODUCTION 5 GENERAL INFORMATION Continued ...

Page 9: ...FASTENER STRENGTH 6 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 11: ...METRIC CONVERSION 8 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 12: ...TORQUE SPECIFICATIONS NS INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 16: ......

Page 26: ......

Page 93: ...RED BRAKE WARNING LAMP FUNCTION NS BRAKES 5 11 DIAGNOSIS AND TESTING Continued ...

Page 94: ...POWER BRAKE SYSTEM DIAGNOSTICS 5 12 BRAKES NS DIAGNOSIS AND TESTING Continued ...

Page 95: ...VEHICLE ROAD TEST BRAKE NOISE NS BRAKES 5 13 DIAGNOSIS AND TESTING Continued ...

Page 222: ...COOLING SYSTEM DIAGNOSIS 7 8 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 223: ...NS COOLING SYSTEM 7 9 DIAGNOSIS AND TESTING Continued ...

Page 224: ...7 10 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 225: ...NS COOLING SYSTEM 7 11 DIAGNOSIS AND TESTING Continued ...

Page 226: ...7 12 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 280: ......

Page 286: ......

Page 289: ...CHARGING SYSTEM SCHEMATIC TYPICAL NS CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 291: ...CHARGING SYSTEM TEST NS CHARGING SYSTEM 8C 5 DIAGNOSIS AND TESTING Continued ...

Page 292: ...OVERCHARGE TEST 8C 6 CHARGING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 294: ...VOLTAGE DROP TEST 8C 8 CHARGING SYSTEM NS ...

Page 298: ......

Page 372: ......

Page 377: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 5 DIAGNOSIS AND TESTING Continued ...

Page 378: ...8E 6 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 379: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 7 DIAGNOSIS AND TESTING Continued ...

Page 380: ...8E 8 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 381: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 9 DIAGNOSIS AND TESTING Continued ...

Page 382: ...8E 10 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 383: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 11 DIAGNOSIS AND TESTING Continued ...

Page 384: ...8E 12 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 385: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 13 DIAGNOSIS AND TESTING Continued ...

Page 386: ...8E 14 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 402: ......

Page 428: ......

Page 440: ......

Page 478: ......

Page 496: ......

Page 504: ......

Page 508: ......

Page 524: ......

Page 542: ......

Page 546: ......

Page 550: ......

Page 559: ...SPECIAL TOOLS SPECIAL TOOL Degausser 6029 NS OVERHEAD CONSOLE 8V 9 ...

Page 560: ......

Page 562: ......

Page 564: ...8W 01 2 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Page 565: ...NS GS 8W 01 GENERAL INFORMATION 8W 01 3 DESCRIPTION AND OPERATION Continued ...

Page 580: ......

Page 616: ......

Page 660: ......

Page 664: ......

Page 704: ......

Page 718: ......

Page 728: ......

Page 740: ......

Page 744: ......

Page 758: ......

Page 768: ......

Page 784: ......

Page 792: ......

Page 796: ......

Page 800: ......

Page 814: ......

Page 822: ......

Page 826: ......

Page 832: ......

Page 836: ......

Page 840: ......

Page 876: ......

Page 1024: ......

Page 1220: ...Fig 3 Lubrication Lines 9 42 ENGINE NS GS DESCRIPTION AND OPERATION Continued ...

Page 1224: ...ENGINE DIAGNOSIS MECHANICAL CONT 9 46 ENGINE NS GS DIAGNOSIS AND TESTING Continued ...

Page 1286: ...Fig 5 Front Crossmember Dimensions 13 6 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Page 1287: ...Fig 6 Engine Compartment Top View NS FRAME AND BUMPERS 13 7 SPECIFICATIONS Continued ...

Page 1289: ...Fig 8 Full Vehicle Bottom View NS FRAME AND BUMPERS 13 9 SPECIFICATIONS Continued ...

Page 1291: ...Fig 11 Body Side Openings NS FRAME AND BUMPERS 13 11 SPECIFICATIONS Continued ...

Page 1292: ......

Page 1302: ...FUEL PRESSURE BELOW SPECIFICATIONS 14 8 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1304: ...FUEL INJECTOR DIAGNOSIS 14 10 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1368: ......

Page 1426: ......

Page 1472: ......

Page 1479: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 5 DIAGNOSIS AND TESTING Continued ...

Page 1480: ...Diagnosis Guide 21 6 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1481: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 7 DIAGNOSIS AND TESTING Continued ...

Page 1482: ...Diagnosis Guide 21 8 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1483: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 9 DIAGNOSIS AND TESTING Continued ...

Page 1484: ...Diagnosis Guide 21 10 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1485: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 11 DIAGNOSIS AND TESTING Continued ...

Page 1486: ...Diagnosis Guide 21 12 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1656: ......

Page 1723: ...LEAD CORRECTION CHART NS TIRES AND WHEELS 22 5 DIAGNOSIS AND TESTING Continued ...

Page 1726: ...SPECIFICATIONS TIRE SPECIFICATIONS 22 8 TIRES AND WHEELS NS ...

Page 1866: ......

Page 1904: ......

Page 1928: ......