(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vacula

y

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Add 4 Quarts of Mopar ATF Plus 3 Type 7176

transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range.

TRANSAXLE OIL PAN DROP METHOD

This procedure involves removing the transaxle oil

pan to drain the transaxle fluid.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N

•

m (165 in. lbs.).

(6) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range. Drive the vehicle a minimum of 10

miles.

(10) Raise the vehicle on the hoist.

(11) Check for leaks around the transaxle oil pan

sealing surfaces.

(12) Recheck the fluid level. The level should be in

the HOT range.

SEVERE USAGE SERVICE

If the vehicle exhibits any of the following symp-

toms, it is recommended that the transaxle oil and

filter be replaced.

•

Transaxle oil discolored

•

Transaxle oil has high mileage

•

Oil feels grimy when rubbed between fingertips

•

Poor shift quality

•

Delayed gear engagement

•

Vehicle shudder between shifts

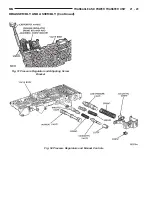

TRANSAXLE OIL AND FILTER REPLACEMENT

This procedure involves changing the transaxle

fluid and filter, driving the vehicle for 10 miles and

changing the transaxle fluid a second time.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Separate the filter and O-ring from the valve

body. Inspect the O-ring for cuts or improper instal-

lation. This could lead to delayed garage shifts.

(6) Install a new filter. Replace the O-ring as nec-

essary.

(7) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N

•

m (165 in. lbs.).

(8) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(9) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(10) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(11) Recheck the fluid level after the transaxle is

at normal operating temperature. The level should be

in the HOT range. Drive the vehicle a minimum of

10 miles.

(12) Raise the vehicle on the hoist.

NS

TRANSAXLE AND POWER TRANSFER UNIT

21 - 17

SERVICE PROCEDURES (Continued)

Summary of Contents for 1998 Voyager

Page 8: ...FASTENER IDENTIFICATION NS INTRODUCTION 5 GENERAL INFORMATION Continued ...

Page 9: ...FASTENER STRENGTH 6 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 11: ...METRIC CONVERSION 8 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 12: ...TORQUE SPECIFICATIONS NS INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 16: ......

Page 26: ......

Page 93: ...RED BRAKE WARNING LAMP FUNCTION NS BRAKES 5 11 DIAGNOSIS AND TESTING Continued ...

Page 94: ...POWER BRAKE SYSTEM DIAGNOSTICS 5 12 BRAKES NS DIAGNOSIS AND TESTING Continued ...

Page 95: ...VEHICLE ROAD TEST BRAKE NOISE NS BRAKES 5 13 DIAGNOSIS AND TESTING Continued ...

Page 222: ...COOLING SYSTEM DIAGNOSIS 7 8 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 223: ...NS COOLING SYSTEM 7 9 DIAGNOSIS AND TESTING Continued ...

Page 224: ...7 10 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 225: ...NS COOLING SYSTEM 7 11 DIAGNOSIS AND TESTING Continued ...

Page 226: ...7 12 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 280: ......

Page 286: ......

Page 289: ...CHARGING SYSTEM SCHEMATIC TYPICAL NS CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 291: ...CHARGING SYSTEM TEST NS CHARGING SYSTEM 8C 5 DIAGNOSIS AND TESTING Continued ...

Page 292: ...OVERCHARGE TEST 8C 6 CHARGING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 294: ...VOLTAGE DROP TEST 8C 8 CHARGING SYSTEM NS ...

Page 298: ......

Page 372: ......

Page 377: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 5 DIAGNOSIS AND TESTING Continued ...

Page 378: ...8E 6 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 379: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 7 DIAGNOSIS AND TESTING Continued ...

Page 380: ...8E 8 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 381: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 9 DIAGNOSIS AND TESTING Continued ...

Page 382: ...8E 10 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 383: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 11 DIAGNOSIS AND TESTING Continued ...

Page 384: ...8E 12 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 385: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 13 DIAGNOSIS AND TESTING Continued ...

Page 386: ...8E 14 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 402: ......

Page 428: ......

Page 440: ......

Page 478: ......

Page 496: ......

Page 504: ......

Page 508: ......

Page 524: ......

Page 542: ......

Page 546: ......

Page 550: ......

Page 559: ...SPECIAL TOOLS SPECIAL TOOL Degausser 6029 NS OVERHEAD CONSOLE 8V 9 ...

Page 560: ......

Page 562: ......

Page 564: ...8W 01 2 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Page 565: ...NS GS 8W 01 GENERAL INFORMATION 8W 01 3 DESCRIPTION AND OPERATION Continued ...

Page 580: ......

Page 616: ......

Page 660: ......

Page 664: ......

Page 704: ......

Page 718: ......

Page 728: ......

Page 740: ......

Page 744: ......

Page 758: ......

Page 768: ......

Page 784: ......

Page 792: ......

Page 796: ......

Page 800: ......

Page 814: ......

Page 822: ......

Page 826: ......

Page 832: ......

Page 836: ......

Page 840: ......

Page 876: ......

Page 1024: ......

Page 1220: ...Fig 3 Lubrication Lines 9 42 ENGINE NS GS DESCRIPTION AND OPERATION Continued ...

Page 1224: ...ENGINE DIAGNOSIS MECHANICAL CONT 9 46 ENGINE NS GS DIAGNOSIS AND TESTING Continued ...

Page 1286: ...Fig 5 Front Crossmember Dimensions 13 6 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Page 1287: ...Fig 6 Engine Compartment Top View NS FRAME AND BUMPERS 13 7 SPECIFICATIONS Continued ...

Page 1289: ...Fig 8 Full Vehicle Bottom View NS FRAME AND BUMPERS 13 9 SPECIFICATIONS Continued ...

Page 1291: ...Fig 11 Body Side Openings NS FRAME AND BUMPERS 13 11 SPECIFICATIONS Continued ...

Page 1292: ......

Page 1302: ...FUEL PRESSURE BELOW SPECIFICATIONS 14 8 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1304: ...FUEL INJECTOR DIAGNOSIS 14 10 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1368: ......

Page 1426: ......

Page 1472: ......

Page 1479: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 5 DIAGNOSIS AND TESTING Continued ...

Page 1480: ...Diagnosis Guide 21 6 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1481: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 7 DIAGNOSIS AND TESTING Continued ...

Page 1482: ...Diagnosis Guide 21 8 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1483: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 9 DIAGNOSIS AND TESTING Continued ...

Page 1484: ...Diagnosis Guide 21 10 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1485: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 11 DIAGNOSIS AND TESTING Continued ...

Page 1486: ...Diagnosis Guide 21 12 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1656: ......

Page 1723: ...LEAD CORRECTION CHART NS TIRES AND WHEELS 22 5 DIAGNOSIS AND TESTING Continued ...

Page 1726: ...SPECIFICATIONS TIRE SPECIFICATIONS 22 8 TIRES AND WHEELS NS ...

Page 1866: ......

Page 1904: ......

Page 1928: ......