FITTING CONNECTING ROD BEARINGS

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. The

following is the recommended procedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig. 10). In addition, suspect areas can

be checked by placing plastigage in the suspect area.

(4) Before assembling the rod cap with Plastigage

in place, the crankshaft must be rotated until the

connecting rod being checked starts moving toward

the top of the engine. Only then should the cap be

assembled and torqued to specifications. Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 10) with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications. Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

(6) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (.001-.003 in.) is usually

the most appropriate for checking engine bearing

proper specifications.

FITTING MAIN BEARINGS

Refer to the Engine General Information Section

for Measuring Main Bearings. For Crankshaft speci-

fications refer to Crankshaft Specification Table.

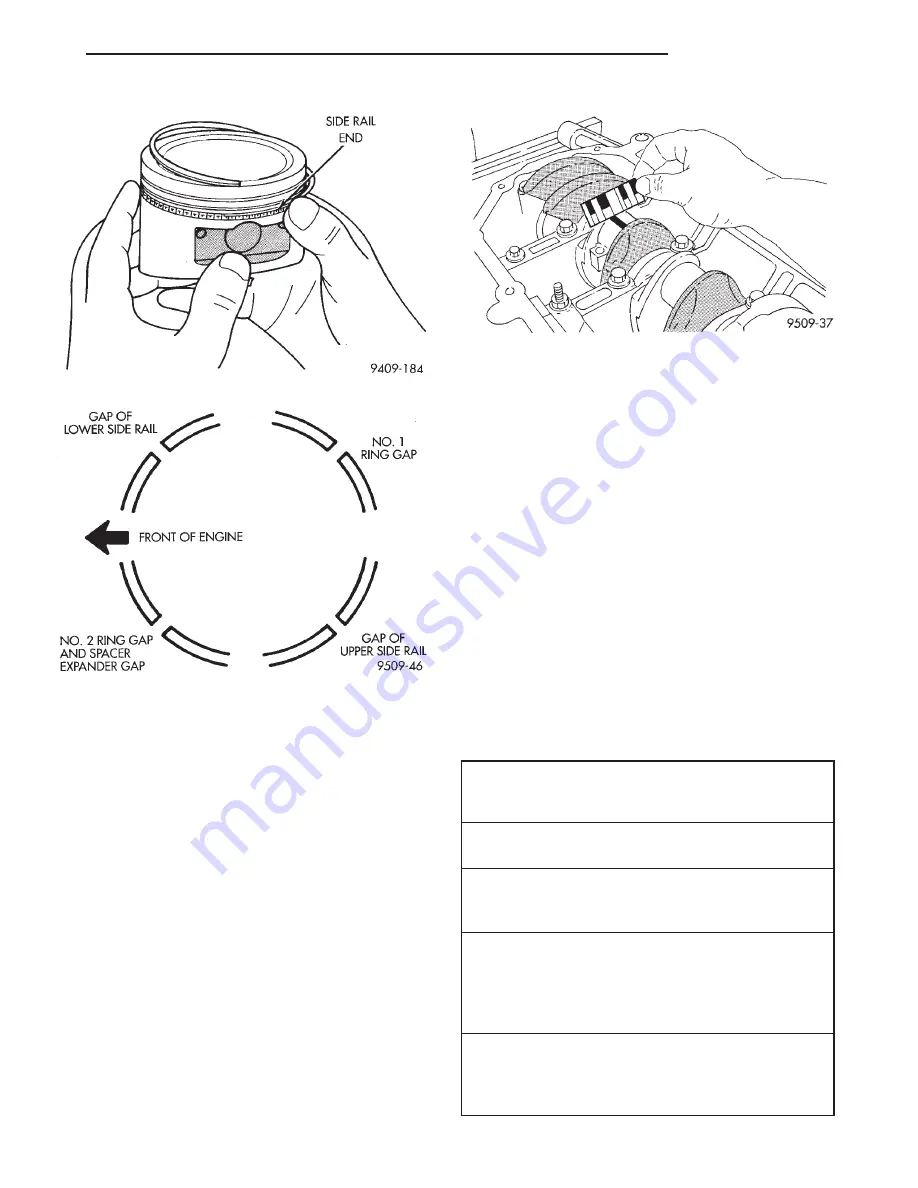

Fig. 8 Installing Side Rail

SIDE RAIL END

Fig. 9 Piston Ring End Gap Position

GAP OF LOWER

SIDE RAIL

NO. 1 RING GAP

GAP OF UPPER

SIDE RAIL

NO. 2 RING GAP AND

SPACER

EXPANDER

GAP

FRONT OF ENGINE

Fig. 10 Measuring Plastigage Width

CRANKSHAFT SPECIFICATION TABLE

Crankshaft End-Play

New Part: 0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Wear Limit: 0.37 mm (0.015 in.)

Main Bearing Clearance

New Part: 0.018 - 0.058 mm (0.0007 - 0.0023 in.)

Connecting Rod Bearing Clearance

New Part: 0.025 - 0.071 mm (0.001 - 0.003 in.)

Wear Limit: 0.075 mm (0.003 in.)

Crankshaft Journal Sizes

Main Bearing Journal Diameter

Standard 60.000

6

0.008 mm (2.3622

6

0.0003 in.)

1 st Undersize 59.975

6

0.008 mm (2.361

6

0.0003

in.)

Connecting Rod Journals

Standard 49.992

6

0.008 mm (1.968

6

0.0003 in.)

1 st Undersize 49.967

6

0.008 mm (1.967

6

0.0003

in.)

JX

2.4L ENGINE

9 - 17

SERVICE PROCEDURES (Continued)

Summary of Contents for 1997 Stratus Convertible LHD

Page 22: ......

Page 186: ......

Page 224: ......

Page 234: ......

Page 237: ...Charging System Schematic Typical JX CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 246: ......

Page 320: ......

Page 326: ......

Page 333: ...Fig 9 Wiper Motor Test JX WINDSHIELD WIPERS AND WASHERS 8K 7 DIAGNOSIS AND TESTING Continued ...

Page 358: ......

Page 380: ......

Page 386: ......

Page 396: ......

Page 398: ......

Page 414: ......

Page 464: ......

Page 468: ......

Page 472: ......

Page 496: ......

Page 532: ......

Page 536: ......

Page 572: ......

Page 584: ......

Page 592: ......

Page 598: ......

Page 610: ......

Page 624: ......

Page 628: ......

Page 632: ......

Page 636: ......

Page 640: ......

Page 702: ......

Page 726: ......

Page 733: ...Fig 8 Body Splices JX 8W 95 SPLICE LOCATIONS 8W 95 7 DESCRIPTION AND OPERATION Continued ...

Page 734: ...Fig 9 Rear Body Splices 8W 95 8 8W 95 SPLICE LOCATIONS JX DESCRIPTION AND OPERATION Continued ...

Page 735: ...Fig 10 Door Splices JX 8W 95 SPLICE LOCATIONS 8W 95 9 DESCRIPTION AND OPERATION Continued ...

Page 736: ......

Page 913: ...Fuel Line Adapter 1 4 JX FUEL SYSTEM 14 59 SPECIAL TOOLS Continued ...

Page 914: ......

Page 1033: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 65 SCHEMATICS AND DIAGRAMS Continued ...

Page 1034: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 66 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1035: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 67 SCHEMATICS AND DIAGRAMS Continued ...

Page 1036: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 68 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1037: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 69 SCHEMATICS AND DIAGRAMS Continued ...

Page 1038: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 70 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1039: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 71 SCHEMATICS AND DIAGRAMS Continued ...

Page 1040: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 72 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1041: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 73 SCHEMATICS AND DIAGRAMS Continued ...

Page 1042: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 74 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1043: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 75 SCHEMATICS AND DIAGRAMS Continued ...

Page 1044: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 76 TRANSAXLE JX SCHEMATICS AND DIAGRAMS Continued ...

Page 1045: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JX TRANSAXLE 21 77 SCHEMATICS AND DIAGRAMS Continued ...

Page 1054: ......

Page 1070: ......

Page 1166: ......

Page 1169: ...JX EMISSION CONTROL SYSTEMS 25 3 DESCRIPTION AND OPERATION Continued ...

Page 1196: ......