23

Section 1 - Outdoor Furnace Installation

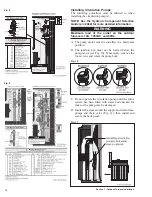

Pressurized Boiler System Installations

Water-to-Water Heat Transfer System

To keep the existing system pressurized, a plate

exchanger or tube & shell water-to-water heat exchanger

installed in the return line of the existing system may be

used (see Fig. 25 and 26). The water from the existing

system passes through the heat exchanger when the

thermostat calls for heat. The water from the outdoor

furnace circulates through the other side of the heat

exchanger continuously.

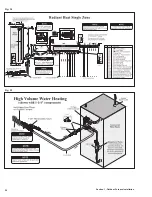

It may be necessary to lower the water temperature at

which the burner in the existing boiler starts to a setting

that prevents the burner in the existing boiler from

cycling on when the outdoor furnace is heating the home.

Another option is to install a thermostatically controlled

interlock switch that prevents the burner in the existing

boiler from operating when the water temperature in the

outdoor furnace is above 150˚F (66˚C).

Water-to-water heat exchangers will produce transfer

temperatures approximately 20ºF (11˚C) less than the

outdoor furnace water temperature; therefore if the

outdoor furnace water temperature is 185°F (85˚C),

it will produce approximately 165°F (74˚C) of water

temperature transfer. The temperature controller on the

outdoor furnace may be adjusted to allow the outdoor

furnace to reach water temperatures up to 195ºF (91˚C).

Each system will vary in water temperature transfer

depending upon the heat load of the existing heating

system.

The addition of a wraparound pump with a water-to-

water heat exchanger (see Fig. 25) may increase heat

transfer by allowing circulation continuously through

the existing boiler and heat exchanger. This will maintain

the maximum temperature in the heat exchanger for

heat transfer to the existing boiler. Note the water flows

in opposite directions through the heat exchanger.

With this type of installation, the exchange temperature

may be more than 165°F (74˚C) and may eliminate the

need for additional baseboard heaters, panel radiators or

heat exchangers.

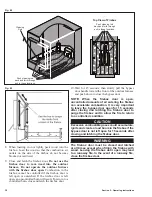

When installing water-to-water heat exchangers, be

sure to flush any rust particles or sediments out of the

existing boiler and install a Y-strainer as illustrated in

Fig. 25. Also be sure to add Corrosion Inhibitor Plus™

(p/n 1650).

A Taco 007 pump can be used as a wraparound pump

when a plate exchanger is installed. A Taco 009 pump

should be used when a shell and tube heat exchanger

(i.e., p/n 148, 151 or 177) is installed.

NOTE: See the Hydronic Component Selection

Guide (p/n 2482) for more detailed information.

Plate Exchanger

Fig. 25

Summary of Contents for e-Classic 1450 IR

Page 17: ...15 Section 1 Outdoor Furnace Installation...

Page 29: ...27 Section 1 Outdoor Furnace Installation Fig 30 Fig 31...

Page 30: ...28 Section 1 Outdoor Furnace Installation Fig 32 Fig 33...

Page 66: ...64 E CLASSIC 1450 WIRING DIAGRAM Section 6 General Information...

Page 67: ...65 Section 6 General Information E CLASSIC 1450 WIRING DIAGRAM OPTIONAL POWER IGNITION...

Page 69: ...67 NOTES...

Page 70: ...68 NOTES...

Page 71: ...69 NOTES...